發佈日期 2024-04-23

應用實績 : ChemTreat 水處理方案為大型醫療設施節省水、金錢和能源

UNIVERSITY MEDICAL COMPLEX SAVES $500K IN ANNUAL WATER COSTS WITH CHEMTREAT PROGRAM

Source : ChemTreat US

The Problem 問題需求

某大型大學醫療中心複合設施需要更換十幾座老化的冷卻塔並新增十座新建物,在過渡期間採用一集中型冷卻水機組。

作為此新系統的一部分,此設施的補充水來自五個來源,而每個來源都有其不同的水質特性:

• 城市供水

• 可用的溪水

• 收集的雨水

• 回收凝結水

• 回收、逆滲透過濾的排污水

機組設施人員同時希望透過延長 RO 膜和預過濾器濾芯的使用壽命、改進系統監控以及減少水垢和腐蝕以節省成本,並提高水處理計劃的永續性。

A major university medical complex needed to replace more than a dozen aging cooling towers and add ten new buildings, all while transitioning to a centrally located chiller plant.

As part of this new system, the facility wanted makeup water to come from five sources, each with varying water quality properties:

• City water

• Available creek water

• Collected rainwater

• Retrieved condensate

• Reused, RO-filtered blowdown water

Facility personnel were also looking to save on costs and improve the sustainability of their water treatment program by extending the life of RO membranes and pre-filter cartridges, improving system monitoring, and reducing scale and corrosion.

The Solution 解決方案

先前的處理工藝無法滿足此新的 32,000 噸集中水處理設施需要處理多個補給水源的需求。

該醫學大學與 CHEMTREAT 合作,為該項計畫提供深入的專業知識和現場支援。

經過徹底的系統評估後,CHEMTREAT 團隊提供一份建議清單,並與該醫學大學共同合作實施改進。

CHEMTREAT 的建議方案包括:

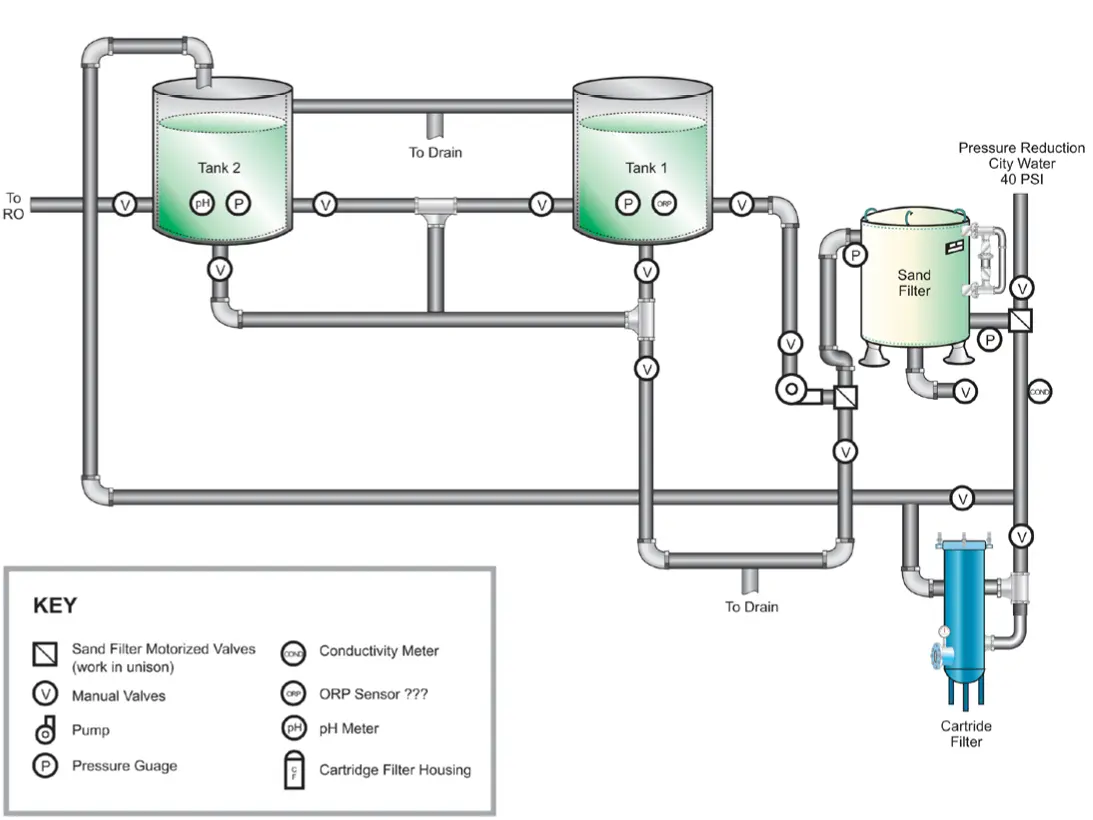

•將逆滲透過濾系統相關的砂濾器重新調整位置。

•增加1 微米過濾器來補強5 微米過濾器以去除懸浮固體(RO 膜效率的限制因素),延長兩次清潔之間的過濾運作時間。

• 運用CTVISTA® 智慧水管理軟體來解決通訊問題。

• 提升冷卻水處理計劃,以管理五個不同補充水源的不同水質。

The previous process was not capable of handling a new 32,000-ton centralized plant using multiple makeup water sources.

The university partnered with ChemTreat for in-depth expertise and on-site support with this project.

After a thorough system evaluation, the ChemTreat team provided a list of recommendations and worked with the university to implement the improvements.

ChemTreat’s recommendations included:

• Repositioning a sand filter in relation to the RO filtration system.

• Adding 1-micron filters to supplement the 5-micron filters for suspended solids removal (a limiting factor for RO membrane efficiency) to extend filtration run duration between cleanings.

• Implementing CTVista® intelligent water management software to solve communication issues.

• Enhancing the cooling treatment program to manage the variable water quality of five different makeup sources.

• Repositioning a sand filter in relation to the RO filtration system.

• Adding 1-micron filters to supplement the 5-micron filters for suspended solids removal (a limiting factor for RO membrane efficiency) to extend filtration run duration between cleanings.

• Implementing CTVista® intelligent water management software to solve communication issues.

• Enhancing the cooling treatment program to manage the variable water quality of five different makeup sources.

The Results 結果

重新設計的預處理工藝 :

• 預處理濾芯的使用壽命從三天延長至一個月以上。

• 離線清潔時間從每週四次五小時減少到每三週僅需三小時,進而減少停機時間、系統中斷和成本。

• 預處理濾芯的使用壽命從三天延長至一個月以上。

• 離線清潔時間從每週四次五小時減少到每三週僅需三小時,進而減少停機時間、系統中斷和成本。

安裝CVISTA監控系統 :

在安裝了 CTVISTA監控系統之後,所有擁有資料存取權限的團隊成員都可以在集中式系統中編寫報告和其他觀察結果,所有計劃參與者得以檢查資料並確定適當的行動方案。

在安裝了 CTVISTA監控系統之後,所有擁有資料存取權限的團隊成員都可以在集中式系統中編寫報告和其他觀察結果,所有計劃參與者得以檢查資料並確定適當的行動方案。

REDESIGNED PRETREATMENT PROCESS

• Pretreatment cartridge life extended from three days to over a month.

• Off-line cleaning times reduced from five hours four times per week to just three hours every three weeks, reducing downtime, system disruptions, and costs.

CTVISTA MONITORING SYSTEM IMPLEMENTATION

Thanks to the installation of CTVista, all team members with data access could write reports and other observations within a centralized system, allowing all program participants to review data and determine the appropriate course of action.

COOLING TREATMENT PROGRAM ENHANCEMENTS

• Biocide program improvements reduced bacteria counts from 103 cfu/mL to 102 cfu/mL.

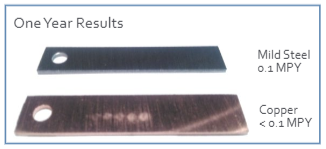

• A consistent corrosion rate of <0.1 mpy established.

• Conductivity maintained at a consistent level throughout multiple water sources.

• Biocide program improvements reduced bacteria counts from 103 cfu/mL to 102 cfu/mL.

• A consistent corrosion rate of <0.1 mpy established.

• Conductivity maintained at a consistent level throughout multiple water sources.

WATER SAVINGS 節省用水

在 CHEMTREAT 的支持下,該醫學大學透過水處理技術的改善,每年節省超過 50 萬美元的水費。

此水再生專案每年節省的水量:

• >1200 萬加侖冷凝水

• >2000萬加侖的溪水

• >2500萬加侖回收排污水

• >1200 萬加侖冷凝水

• >2000萬加侖的溪水

• >2500萬加侖回收排污水

With ChemTreat’s support, the university was able to save over $500,000 per year in water costs thanks to improvements to its water treatment processes.

Annual water savings from reclamation projects:

• >12 million gallons of condensate

• >20 million gallons of creek water

• >25 million gallons of recovered blowdown

• >20 million gallons of creek water

• >25 million gallons of recovered blowdown

Results are examples only. They are not guaranteed. Actual results may vary.

Hach, ChemTreat 同為Veralto集團旗下水質分析事業群