為什麼超純水需要超精確的氯濃度監測? Why Ultrapure Water Demands Ultraprecise Chlorine Analysis

Why Ultrapure Water Demands Ultraprecise Chlorine Analysis

Across a variety of precision-minded industries — semiconductor, pharmaceutical, food, beverage, etc. — concerns about water purity far exceed the demands of municipal drinking water. In applications that depend on reverse osmosis (RO) membranes, and where a delicate chlorination/dechlorination balance demands extreme sensitivity and reliability, new online chlorine analyzers are smoothing the path to more cost efficient performance.

半導體、製藥、食品、飲料等要求精確度的產業對於水純度的關注遠超過民生飲用水的要求。無論是逆滲透((RO)膜的應用、氯化/脫氯的平衡都需要極高的靈敏度和可靠度,新型的水中氯自動分析儀協助達成更具成本效益的效能。

半導體、製藥、食品、飲料等要求精確度的產業對於水純度的關注遠超過民生飲用水的要求。無論是逆滲透((RO)膜的應用、氯化/脫氯的平衡都需要極高的靈敏度和可靠度,新型的水中氯自動分析儀協助達成更具成本效益的效能。

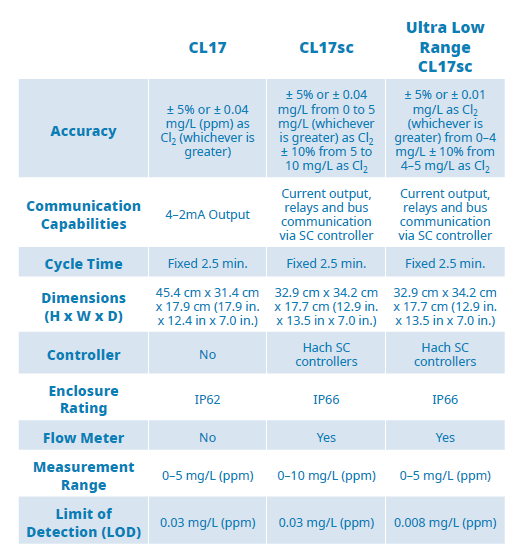

With so many potential negative impacts— from chemical costs to RO membrane damage to excessive quality control rejection rates — it is more important than ever to reevaluate both the inputs and outcomes of chlorine measurement and control. Traditionally, either intermittent grab sample analyses or online measurements of oxidation reduction potential (ORP) are employed for chlorine monitoring. The latter method has suffered from too many variables, and previously available online chlorine analyzers could not achieve the required accuracy at ultra-low chlorine ranges to protect RO membranes efficiently. Now, however, the ability of online chlorine analyzers to measure chlorine concentrations directly as low as 0.008 mg/L (8 parts per billion (ppb)) is opening up new opportunities to provide automatic and accurate readings every 2.5 minutes.

從化學品的成本費用、RO逆滲透膜的損耗,到過高的產品不良率,由於會有許多潛在的負面影響,因此重新評估水中氯濃度的監測以及控制輸入和輸出結果比以往任何時候都更為重要。 傳統上,水中氯濃度監測採用間歇性抓樣分析或線上測量氧化還原電位(ORP)。後者方法經常有太多變數,因此以往的線上氯分析儀無法於超低氯範圍內達到所需的準確度以便有效保護RO膜。如今,新型的氯自動分析儀能夠直接測量低至 0.008 毫克/升 (十億分之 8 (ppb)) 的水中氯濃度,並可以每2.5分鐘提供一次自動準確的讀值數據。

從化學品的成本費用、RO逆滲透膜的損耗,到過高的產品不良率,由於會有許多潛在的負面影響,因此重新評估水中氯濃度的監測以及控制輸入和輸出結果比以往任何時候都更為重要。 傳統上,水中氯濃度監測採用間歇性抓樣分析或線上測量氧化還原電位(ORP)。後者方法經常有太多變數,因此以往的線上氯分析儀無法於超低氯範圍內達到所需的準確度以便有效保護RO膜。如今,新型的氯自動分析儀能夠直接測量低至 0.008 毫克/升 (十億分之 8 (ppb)) 的水中氯濃度,並可以每2.5分鐘提供一次自動準確的讀值數據。

It lets manufacturers : 監測水中超低量測範圍的氯濃度能夠協助製造商:

- Have confidence in using chlorine to control biofouling that can clog membrane pores.有信心地使用氯來控制可能堵塞薄膜孔的生物污垢。

- Detect chlorine as low as 8 ppb with reliable, accurate, proven colorimetric DPD chemistry sensitive enough to maximize membrane service life. 用可靠、準確、經過驗證的比色DPD測試方法來檢測低至 8 ppb 的氯濃度,以最大限度地延長薄膜的使用壽命。

- Obtain accurate digital readouts of total chlorine levels— including a cumulative chlorine counter that tracks chlorine exposure in ppm-hours — without the influence of temperature or pH variables that plague ORP readings. 獲得總氯濃度的準確讀值 - 包括以 ppm-小時為單位追蹤氯接觸。

- Capitalize on comprehensive diagnostics and flow sensing to monitor ongoing instrument operation and receive notification of unexpected changes. 利用全面的診斷和流量感測來監測運行中的儀器操作並接收意外變化的系統通知。

Figure 2. Building upon proven colorimetric DPD technology from previous generations, next-generation

ULR chlorine analyzers provide a more accurate way to automate monitoring of precise chlorine levels

in dechlorination processes meant to protect RO membranes。

Who Can Benefit From Better Chlorine Analysis For Ultrapure Water Consistency? 以下領域的使用者可從更精確監測超純水的氯濃度而獲益

- Semiconductor And Electronics Manufacturing. With dechlorination being so critical for ultrapure water chemistry as well as protection of critical RO membranes, achieving direct chlorine readings at ultra-low ranges from online sensing provides multiple advantages for primary processes and process water reuse. This ASTM International Standard Guide for Ultrapure Water Used in the Electronics and Semiconductor Industries provides water treatment guidelines for achieving increased circuit densities and reducing quality control (QC) rejection rates when growing crystals, slicing wafers, cleaning and etching their surfaces, preparing photomasks, etc.

半導體和電子製造:脫氯對於超純水化學以及重要RO薄膜的保護極為關鍵,對於初級處理和處理水回收,透過線上監測而取得超低量測範圍氯濃度的數據具有多種好處。ASTM美國材料和試驗協會的電子和半導體產業超純水國際標準指南提供了水處理的規範,對於晶體、晶圓切片、清洗和蝕刻表面、製備光罩等製程達到更高的電路密度和降低品管(QC)不良率.

- Pharmaceutical Manufacturing. ULR chlorine analysis helps to achieve cost-effective water treatment for satisfying critical stages of manufacturing and for preparing research formulations for disintegration and dissolution testing. This ASTM International Standard Specification for Reagent Water includes detailed specifications for Types I, II, III, and IV water used in various laboratory and pharmaceutical applications to prevent costly waste from high rejection rates of compromised products.

藥品製造:超低量測範圍氯濃度分析有助於達成具成本效益的水處理,以滿足製造的關鍵階段要求以及為藥物崩散度試驗和溶出度測試的研究配方而準備。ASTM美國材料和試驗協會的國際試劑水標準規範包括用於各種實驗室和製藥應用的Type I、II、III 和 IV 水的詳細規範,以避免因產品的高不良率而造成的昂貴浪費。

- Food And Beverage Applications. In addition to promoting consumer product purity, generating ultrapure water in food and beverage applications affords manufacturers control over the addition of specific minerals to give its products a consistent flavor profile. This is particularly helpful for establishing consistency for flagship global brands, regardless of local water quality where the product is being produced and pack aged.

食品和飲料應用:除了提高消費產品的純度外,生產食品和飲料應用所需的超純水還可讓製造商控制特定礦物質的添加,讓產品的風味維持一致。

- Data Center Cooling. Another growing application for RO filtered and deionized makeup water is for closed- circuit cooling water systems at major data centers. It helps to protect the longevity of the infrastructure and the efficiency of thermal transfer by reducing the potential for both biofouling and mineral deposits

數據資料中心冷卻:RO過濾和去離子補給水的另一個日益增加的應用是大型數據資料中心的閉路冷卻水系統。透過減少生物污垢和礦物質累積的可能性,有助於保護基礎設施的使用壽命以及熱傳遞效率。

Figure 1. With automated operation and sufficient reagent storage,

new ULR chlorine analyzers (Ultra Low Range 超低量測範圍水中氯線上自動分析儀) can provide precise readings of chlorine

concentrations as low as to 8 ppb for up to a month in continuous

production line operations.

new ULR chlorine analyzers (Ultra Low Range 超低量測範圍水中氯線上自動分析儀) can provide precise readings of chlorine

concentrations as low as to 8 ppb for up to a month in continuous

production line operations.

Layout ©Hach Company, 2022. Article ©Water Online (www.wateronline.com). All rights reserved.

原文 :

Why Ultrapure Water Demands Ultraprecise Chlorine Analysis

DOC043.53.30747

DOC043.53.30747