製藥和生技產業水質分析方案 Pharma and Life Sciences

Start-to-Finish Confidence for the Pharmaceutical and Life Sciences Industry

協助您於製藥和生技產業中的每個製程環節,建立信賴可靠的水質分析

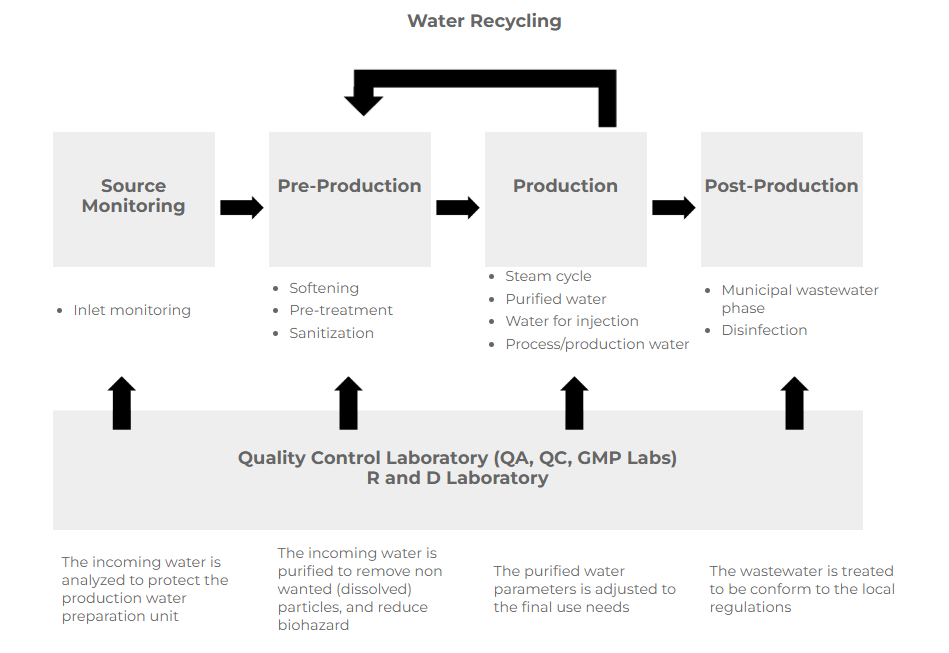

Manufacturing processes in the pharmaceutical and the life sciences industries (small molecules, biologics, medicinal products and medical devices) can require a substantial amount of water. Various water types and testing variables (pH, conductivity, TOC, etc.) make water a more complicated component than one might think.

Ensuring a safe and sterile product is critical regardless of process stage or end application. Through proper monitoring and treatment from the start, you can ensure your quality standards are met at each stage of the process. Real-time analysis during intake can improve process efficiency and quickly determine changes to be made to the incoming water quality and conditioning, filtration effectiveness and microbiological quality

Hach ® provides you the tools to generate accurate, consistent parameter measurements without production interruptions.

製藥和生技產業(小分子、生物製品、醫藥產品和醫療器材)的製造過程可能需要大量的水。 製藥生技產業中的各種水類型和測試變數(pH、導電度、TOC 等)經常是比人們所想像的更複雜。

Ensuring a safe and sterile product is critical regardless of process stage or end application. Through proper monitoring and treatment from the start, you can ensure your quality standards are met at each stage of the process. Real-time analysis during intake can improve process efficiency and quickly determine changes to be made to the incoming water quality and conditioning, filtration effectiveness and microbiological quality

Hach ® provides you the tools to generate accurate, consistent parameter measurements without production interruptions.

製藥和生技產業(小分子、生物製品、醫藥產品和醫療器材)的製造過程可能需要大量的水。 製藥生技產業中的各種水類型和測試變數(pH、導電度、TOC 等)經常是比人們所想像的更複雜。

無論製程階段或最終應用如何,確保產品的安全和無菌都是很關鍵的。 從一開始就進行適當的監測和處理,您可以確保在製程當中的每個階段都達到您的品質標準。 進水期間的即時分析可提高流程效率,協助快速決定根據進水水質、調節、過濾效率和微生物品質來進行調整。

Hach ® 協助您在不需中斷製程的情況下,仍能準確監控關鍵水質參數的設備方案。

Hach Provides Solutions

Our suite of lab and process instrumentation can help you navigate day-to-day routine testing, unforeseen changes and challenges. We can support regulatory compliance needs and help increase safety and effectiveness, while also providing insight to minimize risk and negative impacts.

Hach solutions can help address your pharmaceutical plant’s needs for pure and ultrapure water treatment, steam generation, cooling processes and industrial wastewater management.

Hach的實驗室和線上分析儀器協助您從容應對日常常規測試、不可預見的變化和挑戰。 Hach方案協助您達到法規要求,提高安全性和有效性,因而提供專業洞見以降低風險和負面影響。Hach解決方案協助滿足製藥廠對於純水和超純水處理、蒸汽產生、冷卻過程和工業廢水管理的需求。

Our suite of lab and process instrumentation can help you navigate day-to-day routine testing, unforeseen changes and challenges. We can support regulatory compliance needs and help increase safety and effectiveness, while also providing insight to minimize risk and negative impacts.

Hach solutions can help address your pharmaceutical plant’s needs for pure and ultrapure water treatment, steam generation, cooling processes and industrial wastewater management.

Hach的實驗室和線上分析儀器協助您從容應對日常常規測試、不可預見的變化和挑戰。 Hach方案協助您達到法規要求,提高安全性和有效性,因而提供專業洞見以降低風險和負面影響。Hach解決方案協助滿足製藥廠對於純水和超純水處理、蒸汽產生、冷卻過程和工業廢水管理的需求。

Featured Parameters and Solutions 重要參數與對應分析儀器

Liquid Color 液體色度

Why?

Validation of product compliance according to color specification works to ensure pharmaceutical drug production consistency. Color differences in the product can cause customer concern regarding product quality and safety.

Validation of product compliance according to color specification works to ensure pharmaceutical drug production consistency. Color differences in the product can cause customer concern regarding product quality and safety.

根據色度規範來驗證產品符合法規標準可確保藥品製造的一致性。 產品的顏色差異會引起客戶對產品品質和安全的擔憂。

Where?

• Final production quality control 成品品管

• Raw material quality control 原料品管

View Hach's Solution

Ozone 臭氧

Why?

Ozone sanitation can be a critical element in efficient disinfection and sanitization of water.

Ozone disinfection is considered to be the primary mechanism for the inactivation/destruction of pathogenic organisms to prevent the spread of waterborne diseases. Due to ozone being a very strong oxidant and virucide, it is typically generated onsite due to its instability and rapid decomposition. 1

臭氧衛生是有效消毒和消毒水的關鍵要素。臭氧消毒被認為是鈍化/破壞病原生物以防止水傳播疾病傳播的主要機制。 由於臭氧是一種非常強的氧化劑和殺病毒劑,由於其不穩定性和快速分解,它通常是在現場產生。1

1National Small Flows Clearinghouse. “EPA Wastewater Technology Fact Sheet – Ozone Disinfection.” EPA 832-F-99-063; September 1999 https://www3.epa.gov/npdes/pubs/ozon.pdf

Ozone sanitation can be a critical element in efficient disinfection and sanitization of water.

Ozone disinfection is considered to be the primary mechanism for the inactivation/destruction of pathogenic organisms to prevent the spread of waterborne diseases. Due to ozone being a very strong oxidant and virucide, it is typically generated onsite due to its instability and rapid decomposition. 1

臭氧衛生是有效消毒和消毒水的關鍵要素。臭氧消毒被認為是鈍化/破壞病原生物以防止水傳播疾病傳播的主要機制。 由於臭氧是一種非常強的氧化劑和殺病毒劑,由於其不穩定性和快速分解,它通常是在現場產生。1

1National Small Flows Clearinghouse. “EPA Wastewater Technology Fact Sheet – Ozone Disinfection.” EPA 832-F-99-063; September 1999 https://www3.epa.gov/npdes/pubs/ozon.pdf

Where?

• Pre-production stage 前製階段

• Pre-production stage 前製階段

Conductivity 導電度

Why?

Conductivity analysis is a key parameter for water pureness measurement.

Various cleaning solutions are more conductive than the water used for flushing, making conductivity measurement a logical way to monitor the cleaning steps and the final rinse. It can also provide certainty there are no impurities in your water (e.g. salt impurity).

Hach conductivity solution fully complies with USP 645.

導電度分析是水純度測量的關鍵參數。各種清潔溶液比用於沖洗的水更具導電性,這使得導電度測量成為監控清潔步驟和最終沖洗的方法。 導電度測量還可確定您的水中有沒有雜質(例如鹽雜質)。

Hach導電度分析方案完全符合 USP 645。

Why?

Conductivity analysis is a key parameter for water pureness measurement.

Various cleaning solutions are more conductive than the water used for flushing, making conductivity measurement a logical way to monitor the cleaning steps and the final rinse. It can also provide certainty there are no impurities in your water (e.g. salt impurity).

Hach conductivity solution fully complies with USP 645.

導電度分析是水純度測量的關鍵參數。各種清潔溶液比用於沖洗的水更具導電性,這使得導電度測量成為監控清潔步驟和最終沖洗的方法。 導電度測量還可確定您的水中有沒有雜質(例如鹽雜質)。

Hach導電度分析方案完全符合 USP 645。

Where?

• Pre-production water

• Production water

• Wastewater treatment

Turbidity 濁度

Why?

Turbidity gauges water’s cleanliness by measuring light reflection off of suspended particles – specifically particles such as proteins, minerals, bacteria, algae, dirt and oil. Quality and compliance are just a few reasons to measure turbidity in lab activities and pharmaceutical processing.

濁度透過測量懸浮顆粒(特別是蛋白質、礦物質、細菌、藻類、污垢和油等顆粒)的光反射來衡量水的清潔度。 品質和符合法規僅是在實驗室活動和製藥加工中測量濁度的幾個原因之一。

Turbidity gauges water’s cleanliness by measuring light reflection off of suspended particles – specifically particles such as proteins, minerals, bacteria, algae, dirt and oil. Quality and compliance are just a few reasons to measure turbidity in lab activities and pharmaceutical processing.

濁度透過測量懸浮顆粒(特別是蛋白質、礦物質、細菌、藻類、污垢和油等顆粒)的光反射來衡量水的清潔度。 品質和符合法規僅是在實驗室活動和製藥加工中測量濁度的幾個原因之一。

Where?

• Pre-production process

• Lab monitoring

• Pre-production process

• Lab monitoring

Chlorine 氯

Why?

A strong oxidizing agent, chlorine (Cl 2), is an ideal disinfectant. When used for disinfection, free chlorine forms when chlorine gas is dissolved in water.

Too much chlorine in water can have detrimental effects in pharmaceutical production, membrane treatment processes and other applications. For example, chlorine can damage active pharmaceutical ingredients (API) during production, resulting in poor product quality or product loss. It can also have detrimental effects on other process instrumentation that could be costly to repair and decrease system lifetimes. In addition, chlorine has to be monitored constantly to follow the Clean-In-Place (CIP) procedure.

強氧化劑氯 (Cl 2) 是一種理想的消毒劑。 用於消毒時,氯氣溶於水中形成游離氯。

水中過多的氯會對藥品生產、膜處理工藝和其他應用產生不利影響。 例如,氯會在生產過程中損壞活性藥物成分 (API),導致產品質量差或產品損失。 它還可能對其他過程儀表產生不利影響,這些儀表的維修成本可能很高,並且會縮短系統壽命。 此外,必須不斷監測氯氣以遵循就地清潔 (CIP) 程序。

Where?

• Piping and vessels used in pharmaceutical production

• Piping and vessels used in pharmaceutical production

View Hach's Solution

CL17sc 水中餘氯/總氯自動分析儀

CL17sc 水中餘氯/總氯自動分析儀

TOC 總有機碳

Why?

High TOC concentrations in water can significantly impact ecosystems and damage manufacturing equipment when left unchecked and untreated.

Organic compounds can be liquid, dissolved in water, or exist in water as undissolved, suspended material. This organic matter can enter water naturally and through man-made sources/processes.

Organic compounds are precursors for disinfection byproducts (DBP), which are strictly regulated in the water industry.

Measuring TOC makes it possible to implement the right treatment to reduce the formation of DBP to comply with the regulatory requirements.

水中的高 TOC 濃度如果不加以控制和處理,會明顯影響生態系統並損壞製造設備。

有機化合物可以是液體,溶於水中,或是不溶於水的懸浮物質。 這類型有機物可以藉由人為來源/過程等途徑而進入水中。

有機化合物是消毒副產物 (DBP) 的前體,在水工業中受到嚴格監督管理。

測量 TOC 就可以採取正確的處理作為,減少 DBP 的形成,以符合法規要求。

High TOC concentrations in water can significantly impact ecosystems and damage manufacturing equipment when left unchecked and untreated.

Organic compounds can be liquid, dissolved in water, or exist in water as undissolved, suspended material. This organic matter can enter water naturally and through man-made sources/processes.

Organic compounds are precursors for disinfection byproducts (DBP), which are strictly regulated in the water industry.

Measuring TOC makes it possible to implement the right treatment to reduce the formation of DBP to comply with the regulatory requirements.

水中的高 TOC 濃度如果不加以控制和處理,會明顯影響生態系統並損壞製造設備。

有機化合物可以是液體,溶於水中,或是不溶於水的懸浮物質。 這類型有機物可以藉由人為來源/過程等途徑而進入水中。

有機化合物是消毒副產物 (DBP) 的前體,在水工業中受到嚴格監督管理。

測量 TOC 就可以採取正確的處理作為,減少 DBP 的形成,以符合法規要求。

Where?

• Pre-production in pharmaceutical manufacturing

• Production stage water quality confirmation

• Post-production wastewater treatment and lab water measurement

View Hach's Solution

Hach BioTector B7000i 水中總有機碳自動分析儀

Hach BioTector B7000i 水中總有機碳自動分析儀

Lab Instrumentation 實驗室水質分析儀器設備

Why?

Innovation comes from laboratories. Hach provides a full-service line of high-quality instrumentation and equipment to help deliver innovation and accuracy in your laboratory experiments.

Innovation comes from laboratories. Hach provides a full-service line of high-quality instrumentation and equipment to help deliver innovation and accuracy in your laboratory experiments.

Where?

• Drug development stage

• Pre large-scale production

View Hach's Solution

DR3900 Spectrophotometer 分光光度計

DR6000 Spectrophotometer 紫外線可見光分光光度計

HQ2200 Multi-Meter 多參數攜帶型水質分析儀

KF1000 Volumetric Titrator 卡爾費雪(Karl Fischer)滴定儀(卡式水分儀)

DR3900 Spectrophotometer 分光光度計

DR6000 Spectrophotometer 紫外線可見光分光光度計

HQ2200 Multi-Meter 多參數攜帶型水質分析儀

KF1000 Volumetric Titrator 卡爾費雪(Karl Fischer)滴定儀(卡式水分儀)