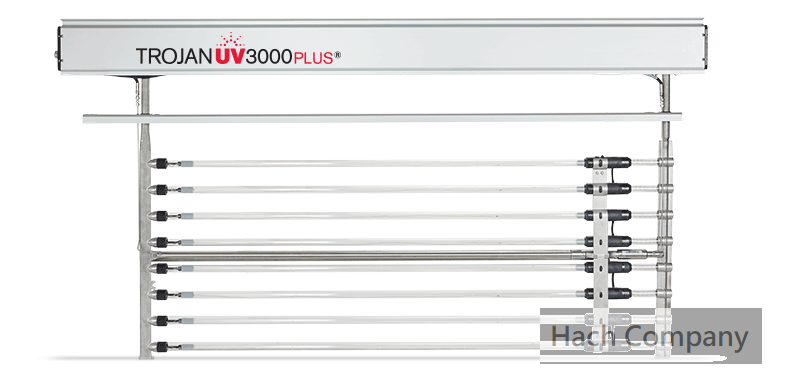

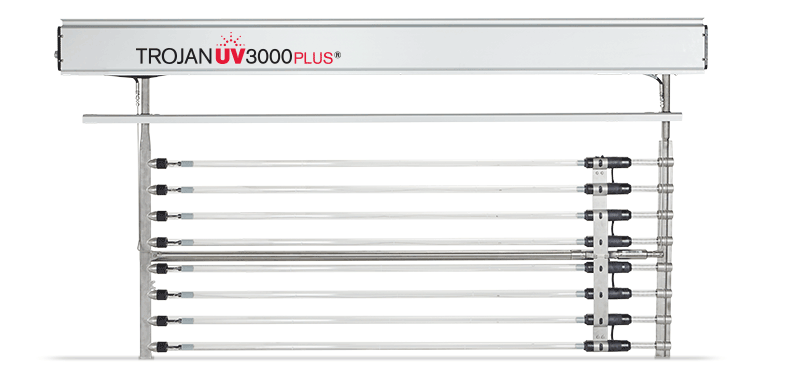

TrojanUV3000Plus 紫外線UV消毒燈

產品編號:

The Next Generation of the TrojanUV3000Plus

The TrojanUV3000Plus® is one of the reasons why UV is now a favored technology in wastewater treatment. As our leading UV system, it has demonstrated effective and reliable performance on six continents where more than 2,000 municipalities rely on it to treat over 30 billion gallons of wastewater every day. TrojanUV3000Plus® 是紫外線於全球六大洲超過 2,000 個城市處理超過 300 億加侖的廢污水,展現有效和可靠的性能。

Since its introduction, we have continued to invest in and evolve the technology and are excited to announce a new generation of the TrojanUV3000Plus product line:

- Built on the same infrastructure that makes it the proven system known today

- Offers new features to simplify operation and maintenance

- Helps plant operators with modern day treatment challenges

Here’s what’s new:

- The new IntegraTM lamp assembly

- Improved ActiClean® sleeve cleaning system

- More system control options including a new TouchSmartTM Plus controller

- Connected Service with Stream™

Applications :

- Secondary & Tertiary Effluent Treatment

- Primary & Low-quality Effluent Treatment

- Non-potable Reuse

The TrojanUV3000Plus® is one of the reasons why UV is now a favored technology in wastewater treatment. As our leading UV system, it has demonstrated effective and reliable performance on six continents where more than 2,000 municipalities rely on it to treat over 30 billion gallons of wastewater every day. TrojanUV3000Plus® 是紫外線於全球六大洲超過 2,000 個城市處理超過 300 億加侖的廢污水,展現有效和可靠的性能。

Since its introduction, we have continued to invest in and evolve the technology and are excited to announce a new generation of the TrojanUV3000Plus product line:

- Built on the same infrastructure that makes it the proven system known today

- Offers new features to simplify operation and maintenance

- Helps plant operators with modern day treatment challenges

Here’s what’s new:

- The new IntegraTM lamp assembly

- Improved ActiClean® sleeve cleaning system

- More system control options including a new TouchSmartTM Plus controller

- Connected Service with Stream™

Applications :

- Secondary & Tertiary Effluent Treatment

- Primary & Low-quality Effluent Treatment

- Non-potable Reuse

Key Features and Benefits

TrojanUV3000Plus Integra Lamp Assembly

Lamps and sleeves are preassembled and factory-sealed together as a single water-tight unit. This reduces the time and complexity of lamp and sleeve replacement and there are fewer parts to inventory and stock. O-rings and seals are permanently built-in, reducing the risk of damage to electrical components by preventing water or moisture from getting inside the assembly. And since you get a clean fresh sleeve with every purchase, you can be sure that nothing stands between the UV light and targeted microorganisms.

Automatic Sleeve Cleaning

Our unique ActiClean system removes fouling from quartz sleeves to ensure the maximum amount of UV light enters the water. ActiClean canisters that hold the cleaning gel are now bigger and more robust, with the ability to hold double the amount of gel for fewer re-fills.

More System Control Options

Operators now have more controller options with new programs and newly designed screens for user-friendly navigation. The new TouchSmart Plus Controller offers a full suite of features and functionality but without the price tag.

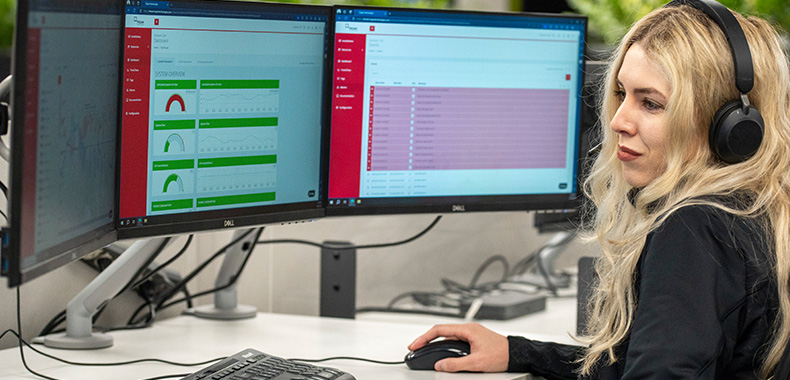

Connected Service with Stream

Stream is our digital network and toolbox that gives you access to the right information and support when and where you need it. The Stream App is your personal view into your UV system; see system status, receive instant alarm notifications and access guided troubleshooting resources. Stream Connection is a support tool that provides our Technical Assistance Center with instant access to your UV system to quickly diagnose and resolve UV issues.

Flexible Installation & Expansion

Modular, compact design allows cost-effective installation into existing effluent channels and chlorine contact chambers. When the time comes to meet new regulations and increase flow capacity, more banks may be added. What’s more – the entire system can be installed outdoors to reduce capital costs, no building, shelter or HVAC required.

Easy to Maintain

UV lamps can be easily and quickly replaced without tools. The preassembled Integra lamp assembly seals water off preventing leaks and premature lamp failures. ActiClean Gel is refilled using a quick connect. Routine maintenance can be performed on one module without disrupting treatment performance of any remaining modules.

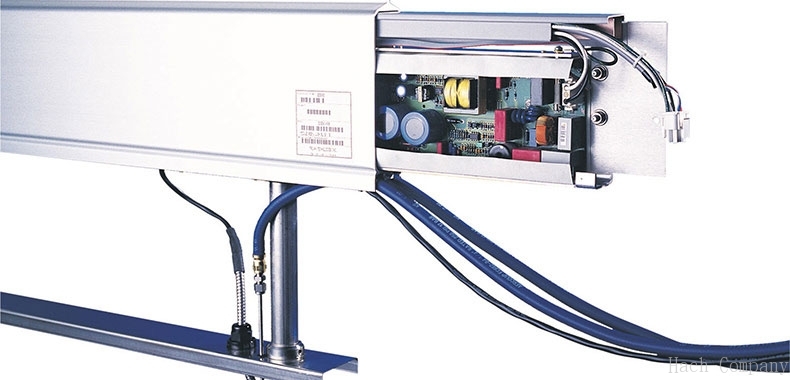

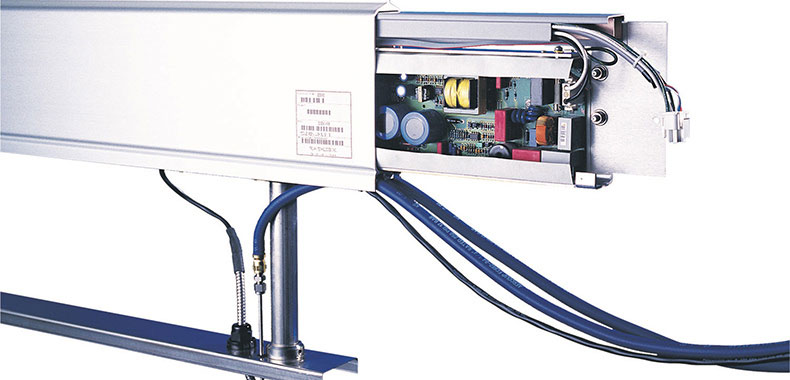

Self-contained UV Modules

Module mounted lamp drivers allow for compact installation and convection cooling. Drivers are housed right in the module eliminating the need for separate external cabinets.

Validation Through Microbial Testing

The TrojanUV3000Plus has been validated through microbial testing. Through this testing, performance data has been generated for UV dose delivery to inactivate microorganisms Escherichia coli (E. coli ) and fecal coliform.

TrojanUV3000Plus module