應用實績>美國俄亥俄州Medina郡水再生廠 - 監測厭氧消化過程有助沼氣產量最佳化

Case Study: Medina County Sanitary Engineers – KJH WRF: Anaerobic Digester Monitoring Helps Avoid Process Upsets and Maximize Biogas Production

Introduction to Anaerobic Digestion 厭氧消化簡介

Anaerobic digestion is a commonly used technology in municipal and industrial solids stabilization processes. Stabilization is a process that reduces the treatment process’ sludge pathogen content, rendering the product safe for beneficial use or disposal. Anaerobic digestion is used in various private industries and is utilized by roughly 10% of all municipal water resource recovery facilities (WRRF).

厭氧消化是民生和工業的固體穩定化過程中常用的技術。 穩定化是一種減少處理過程中污泥病原體含量的過程,使產品可以安全使用或廢棄處置。 厭氧消化應用於各種民營產業,大約10%的民生污水資源回收設施 (WRRF) 使用厭氧消化。

Anaerobic digestion differs from other stabilization processes in its potential to recover energy via captured biogas. Biogas is produced as a byproduct of the digestion process and can be used in boiler systems for heat production, engines/turbines connected to generators for energy generation or even further treated to produce other fuels, such as natural gas. This ability to capture stored energy present in our waste streams makes anaerobic digestion an attractive technology as water resource recovery facilities continue to work towards resource recovery as an integrated aspect to regulatory compliance.

厭氧消化與其他穩定化過程的不同之處在於其透過捕獲的沼氣(生質氣體)回收能量的潛力。 沼氣是消化過程的副產品,可用於鍋爐系統以產生熱量,發動機/渦輪機連接到發電機以產生能源,甚至進一步處理以生產其他燃料,如天然氣。 這種從我們的廢物流中捕獲能量的技術使厭氧消化具有吸引力,而水資源回收單位繼續努力實現資源回收,並成為符合法規的整合面。

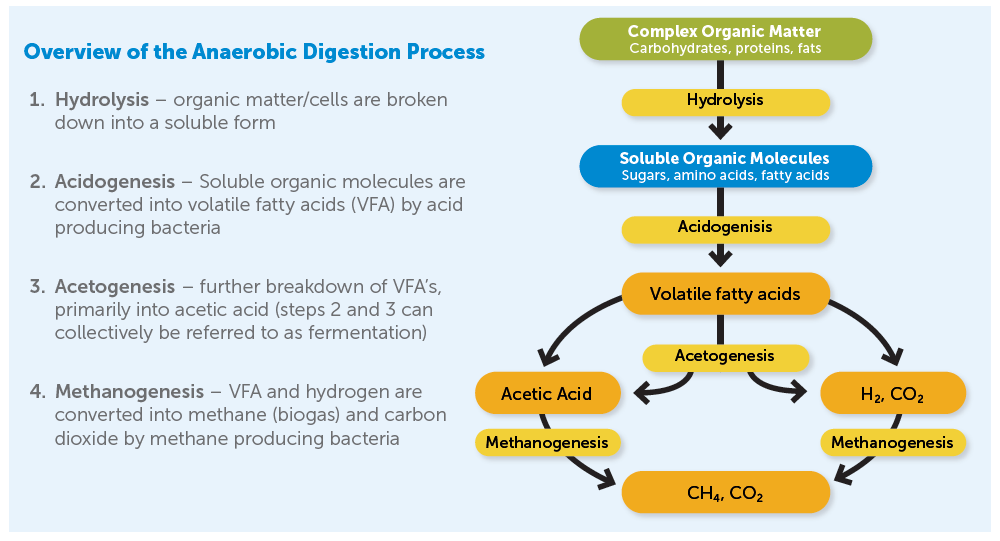

Anaerobic digesters are fed by sludge captured or generated by upstream processes in the WRRF liquid treatment stream as well as captured fats, oils, and greases (FOG) or food/industrial wastes. While there are many specific configurations for anaerobic digesters (mesophilic, thermophilic, etc.) the objective remains the same: create an environment that promotes the controlled and stable decomposition of organic matter via naturally occurring biological pathways. This is accomplished in four simultaneous stages: Hydrolysis, Acidogenesis, Acetogenesis, and Methanogenesis.

厭氧消化槽的供料來自於 WRRF(民生污水資源回收設施)液體處理流的上游過程中所捕獲或產生的污泥以及捕獲的脂肪、油和油脂 (FOG) 或食品/工業廢物。 雖然厭氧消化器有許多特定的配置(中溫、嗜熱等),但其目標保持不變:創造一個透過自然發生的生物途徑促進有機物的受控和穩定分解的環境,並在四個同步階段完成:水解、產酸、產乙酸和產甲烷。

Methane forming bacteria are sensitive to many process conditions, including temperature, pH, and the presence of various toxins. Optimal performance occurs within a pH range of 6.8-7.2. If pH levels drop in the digester, the methane-formers can be inhibited, halting the digestion process and biogas production altogether.

甲烷形成細菌對於許多程序條件來說是敏感的,包括溫度、pH 值和各種毒素的存在。 最佳效能出現在 6.8-7.2 的 pH 值範圍內。 如果消化槽中的 pH 值下降,可以抑制甲烷形成物,進而完全停止消化過程和沼氣生產。

Medina County Sanitary Engineers supports the public utilities serving the city of Medina, Brunswick, and several other townships. The county maintains three water reclamation facilities, including the newly renamed Kenneth J Hotz WRF, formerly known as the Liverpool Wastewater Treatment Plant. At this site, the county funded upgrades to increase renewable energy capture from their anaerobic digester system.

Medina郡的公衛工程師支援服務Medina市、Brunswick市以及其他幾個鄉鎮的公共事業設施。 Medina郡擁有三個水再生設施,包括新更名的 Kenneth J Hotz WRF,前身為利物浦污水處理廠。 Medina郡資助此水廠的升級以增加從厭氧消化系統中捕獲的可再生能源。

This is generally referred to as digester souring – an odor producing, time consuming, and expensive failure of the system which can often cost tens of thousands of dollars to recover from.

通常此被稱為消化槽酸化 - 一種產生氣味、耗時且代價高昂的系統故障,通常需要數萬美元才能恢復。

Digester stability is greatly increased when high levels of alkalinity are present. Alkalinity is defined as a solutions ability to resist changes in pH in the presence of acids/bases. In anaerobic digesters, alkalinity is consumed during the production of VFA in stage 2 referenced above. Fortunately, bicarbonate alkalinity is produced as the methane-formers convert VFA into methane, as referenced in stage 3 above. Digester operators can maintain a healthy balance between VFA and alkalinity based on carefully monitored operational control of feed rates, mixing, and heating.

當高鹼度存在時,消化槽的穩定度會大大增加。 鹼度定義為溶液在酸/鹼存在下抵抗 pH 變化的能力。 在厭氧消化槽中,在上述第 2 階段中的 VFA 生產過程中會消耗鹼度。 幸運的是,當甲烷形成劑將 VFA 轉化為甲烷時,就會產生碳酸氫鹽鹼度,如上述第 3 階段所述。 根據對進料速率、混合和加熱的仔細監控操作控制,消化槽操作可在 VFA 和鹼度之間保持健康的平衡。

While anaerobic digestion processes are well understood, digester upsets or inefficient energy recovery issues are still challenges commonly faced by operators.

儘管厭氧消化過程已廣為人知,但消化槽故障或能量回收效率低下的問題仍然是操作人員普遍面臨到的挑戰。

Anaerobic digestion efficiency can be substantially improved by implementing pretreatment technologies that lyse the cells being fed into the digester. Cell lysing improves the efficiency, energy capture, environmental sustainability, and solids reduction in the digestion process. One such pretreatment technology is thermal hydrolysis process (THP). This process uses extreme pressure and heat to achieve these results. While pretreatment of anaerobic sludge can vastly improve the digestion process, the system should also be carefully monitored to prevent digester over-feeding.

厭氧消化效率可透過裂解進到消化槽內的細胞的預處理技術而得到顯著改善。 細胞裂解改善消化程序中的效率、能量捕獲、環境永續和減少固體物。 這樣的預處理技術之一是熱水解程序(THP)。 此程序使用極端壓力和熱量來達成結果。 雖然厭氧污泥的預處理可大幅改善消化過程,但也需仔細監測系統以防止消化槽過度進料。

Anaerobic digesters at the Kenneth W. Hotz Water Reclamation Facility

Anaerobic Digester Monitoring 厭氧消化監測

Typical anaerobic digester monitoring consists of periodic grab samples (ideally daily) for laboratory analysis of pH, alkalinity, and VFA. While this may be enough for highly consistent applications, most anaerobic digesters are subject to a high degree of variability in their operational conditions. In such cases, additional monitoring or increased sample frequency may be desired to avoid upsets or simply maximize performance and energy recovery.

典型的厭氧消化槽監測包括定期抓取樣品(最好是每天)來進行實驗室分析 pH、鹼度和 VFA。 雖然這對於高度一致的應用來說可能已經足夠了,但大多數厭氧消化槽的操作條件會受到高度可變性的影響。 在這種情況下,可能需要另外的監控或增加採樣頻率以避免干擾因素或是為了將效能最佳化和能源回收。

Case Study: Medina County Sanitary Engineers – Liverpool WWTP 案例研究:美國俄亥俄州Medina郡 - 利物浦污水處理廠

In the early 2010’s, Phil Cummings (superintendent) and DawnTaylor (assistant superintendent) at the Kenneth W. Hotz Water Reclamation Facility (formerly known as the Liverpool Wastewater Treatment plant) in Medina County, Ohio, faced the challenge of figuring out how to improve their solids handling process. Their incumbent technology consisted of an aging Wet Air Oxidation process that was energy intensive, requiring significant gas and electricity to operate. In conjunction with their consultants, the county decided to move in a direction that would be more environmentally sustainable and energy positive – anaerobic digestion with thermal hydrolysis.

2010年初期,位於美國俄亥俄州Medina郡的 Kenneth W. Hotz 水再生廠 (之前稱為利物浦污水處理廠)的 Phil Cummings(主管)和 DawnTaylor(助理主管)面臨著找出如何改進懸浮固體處理程序的挑戰。 他們當時的技術包括老化的濕式空氣氧化程序 - 能源密集型,需大量的天然氣和電力才能運行。 透過與他們的顧問共同合作,Medina市決定朝向更環保和更積極的方向發展 - 熱水解厭氧消化。

Transitioning from Wastewater Treatment to Resource Recovery 從廢水處理到水回收之轉變

The city decided on anaerobic digesters with Thermal Hydrolysis retreatment to maximize their energy recovery via optimal biogas production and capture. To ensure optimal digester feed rates and to generally monitor digester health continuously, the county began looking for online monitoring technologies to supplement the standard laboratory procedures used in monitoring the health of anaerobic digesters (grab samples for VFA, alkalinity, and pH). After a thorough market search, the plant decided to purchase the Hach EZ7250 Analyzer to monitor digester VFA, Bicarbonate, Alkalinity, and pH in real time. This technology was particularly useful when starting up the THP system to ensure digester feed rates did not result in excessive VFA production, which could lead to inhibiting pH levels for the methane-forming bacteria, while also ensuring maximum biogas production.

Medina市決定採用熱水解再處理的厭氧消化槽,透過沼氣產量和捕獲最佳化以獲得最大的能源回收。 為確保消化槽的最佳進料速率並持續監測消化槽的狀況,Medina郡開始查找線上監測技術以補充其用於監測厭氧消化槽的標準實驗室程序(採集揮發性脂肪酸、鹼度和 pH 值的水樣)。 經過詳細的市場研究,此再生水廠決定採購Hach EZ7250 自動分析儀來即時監測消化槽的揮發性脂肪酸、碳酸氫鹽、鹼度和 pH 值。 此技術在啟動 THP 系統時特別有幫助,因可確保消化槽進料的速率不會導致產生過多的揮發性脂肪酸,因其可能會導致抑制甲烷形成細菌的 pH 值,所以同時確保了沼氣產量最大化。

Hach EZ7250 Analyzer and EZ9130 Filtration System Overview Hach EZ7250 分析儀和 EZ9130 過濾系統

The plant staff regularly sampled the digester using following laboratory methods:

廠區人員使用以下實驗室方法來定期對消化槽進行採樣:

• VFA 揮發性脂肪酸 - Hach TNTPlus™ (TNT872) using the esterification method (Method 10240).

• Alkalinity 鹼度 – Buret titration, Standard Method 2320 B-97

• Bicarbonate碳酸氫鹽 – Not tested in lab

• pH – via pH electrode

A Real-world Example 真實範例

Engineering estimates predict a reduction in energy related costs of ~$1.5 million a year (roughly 30% of the facility’s energy requirements). These savings coupled with the potential for additional biogas production and from industrial partnerships are not only enough to prevent rate increases for customers, but also help promote future adoption of sustainable resource recovery projects throughout the water treatment community.

工程估算預測能源相關成本每年可減少約 150 萬美元(約佔廠區能源需求的 30%)。 這些成本節省加上額外沼氣生產以及和工業合作夥伴關係的潛值,不僅防止客戶的費率增加,並且幫助推廣水處理界未來採用永續資源回收專案。

Conclusions 結論

Highly accurate and reliable online instrumentation for anaerobic digester health can provide the following benefits to system managers and operators:

採用高度準確和可靠的線上分析儀來監測厭氧消化槽的運作狀態可為水處理系統管理人員和操作人員提供以下優勢:

• Minimize system upsets and downtime 將系統故障和停機時間最小化

• Maximize resource recovery efficiencies (where desired) 將水回收效率最大化 (當需要時)

The EZ7250 Anaerobic Digester Monitoring solution, coupled with the EZ9130 Heavy Duty Filtration System, are ideally suited for any anaerobic digestion system and can provide real-time insights into the standard set of challenges faced by operators of anaerobic digesters in any industry. Hach EZ7250 厭氧消化監測與 EZ9130 過濾系統整合方案,非常適合任何厭氧消化系統,並可即時洞察操作人員面對的挑戰。

View of the EZ7250 Analyzer – Online measurement of VFA, Alkalinity, Bicarbonate, and pH in a single run

“By being able to monitor conditions so closely with the analyzer, we were able to quickly optimize the feed rate at startup and needed much less seed sludge as a result. Since the process has stabilized, we have been monitoring the trends and are able to quickly notice any changes. As a result, we have been able to react quickly to unexpected changes and make necessary adjustments to avoid any issues.” -Dawn Taylor, Assistant Superintendent

“透過使用(自動)分析儀密切地監測狀況,我們可以在啟動時就快速優化進料的速率,因此需要更少的種子污泥。 由於程序已穩定,我們持續監控趨勢並可能夠快速發現任何的變化,然後對意外的變化做出快速反應,並進行必要的調整以避免出現任何問題。” -Dawn Taylor, Assistant Superintendent

| Application Notes | Language | Size | Date | Edition |

|---|---|---|---|---|

|

Case Study: Medina County Sanitary Engineers – KJH WRF: Anaerobic Digester Monitoring Helps Avoid Process Upsets and Maximize Biogas Production DOC043.53.30614 |

English US | 1 MB | 2020-05 | May20 |