應用實績>德國製紙廠Steinbeis 採用Hach BioTector B7000i TOC Analyzer 進行TOC自動監測

Steinbeis decides for TOC monitoring with Hach BioTector B7000i

Background 背景介紹

Steinbeis Papier GmbH is a German manufacturer of printer and magazine paper made from 100% recycled content. The company has approx. 350 employees with a production capacity of about 300,000 tons of paper per year. Steinbeis Papier obtains its process water from a major river and discharges it back into the river after cleaning it with a two-stage aerobic treatment process in the company owned, purely industrial wastewater treatment plant. The Hach equipment used on-site include instruments for online monitoring of TSS and ammonium in addition to a Buhler 4011 sampler and DR3900 in the laboratory.

Steinbeis Papier GmbH 是德國一家採用100%回收成份以製成影印紙和雜誌紙的製紙廠。 Steinbeis Papier 製紙廠有約 350名員工,年生產量約為30萬噸紙。 Steinbeis Papier 製紙廠區內有其自有運營的一個工業廢水處理廠。製紙廠平日自鄰近一條主要河流取得製程水源,使用之後於廢水處理廠內透過兩步驟氧化工藝完成廢水淨化處理後,再排放回河中。 Steinbeis Papier 廠區內的實驗室中除Buhler 4011採樣器和DR3900分光光度計外,現場使用的Hach設備還包括線上監測TSS和銨的儀器。

A new TOC device was needed

At Steinbeis Papier the control of the clarification process was automated with an online TOC unit from Hach at the inlet of the wastewater treatment plant. The TOC values, which showed a good correlation with BOD5, were passed to the process control system. The process control system managed the dosage of urea and phosphoric acid in real-time based on volume flow, ammonia levels and TOC values to ensure an optimal nutrient ratio. The company was very satisfied with this solution for many years, but the measuring range of the TOC instrument used (ASTRO-TOC) was often insu-cient and the instrument needed to be replaced due to its age to ensure ongoing reliability of the online TOC values which are essential for the precise control of the plant and trouble-free TOC degradation. They decided to install a new TOC online analyzer which would measure the TOC content in the inlet and outlet of the wastewater treatment plant.

過去多年來,製紙廠對既有的解決方案都很滿意,但其中所使用的TOC線上分析儀器(ASTRO-TOC) 的測量範圍經常不足以因應,且由於其使用年限已至,因而需要汰舊換新,以確保未來所測得的TOC數值具有持續的可靠度。這些TOC監測數值對於製紙廠能準確控制、運行正常且無故障的TOC降解極為關鍵。 因此製紙廠決定安裝新型的TOC線上分析儀,以監測廢水處理廠進水口和排水口的TOC濃度。

First, a unit with high-temperature combustion oxidation at 1,200°C (without catalyst) was installed. Due to the demanding wastewater matrix the commissioning of the device was di¬fficult, and it took about 8 weeks until it delivered usable measurements. Then, after only 14 days, blockages occurred caused by deposits in the reactor.

首先是安裝了一台可在1200℃下高溫燃燒氧化的分析儀器(無催化劑)。 由於廢水水質的要求很高,因此該儀器的調試很困難,且需要約8週才能提供可用的測量值。 然後,安裝僅14天後,分析儀器反應器中的沉積物造成了堵塞。

To remove blockages in TOC devices with high-temperature combustion oxidation, the device must be switched o and the oven needs to cool down. Afterwards the reactor must be manually cleaned before the device is restarted. The whole process takes about 8 hours. During this time no measured values are available, and the clarification process cannot be controlled based on measured values. Even failures cannot be detected during this maintenance work and the responsible employee is bound for several hours.

為了要移除(具高溫燃燒氧化功能)TOC分析儀中的堵塞物,必須先關閉儀器並需要冷卻烤箱。 然後,在重新啟動儀器之前,必須手動清潔反應器。 整個過程約需8個小時。 於此期間,沒有可用的監測值,也就無法根據測量值來控制淨化過程。 而在這段維護工作的期間,自然無法監測到故障,負責管理的員工因而需耗費數小時於現場處理。

Solution

TOC Monitoring with Hach BioTector B7000i

Instead of the high temperature TOC instrument, an online TOC analyzer Hach BioTector B7000i was installed. “The BioTector simply ran after start-up” says the Steinbeis sewage plant manager enthusiastically. Since then, the device has been delivering its measured values reliably without any problems and without manual cleaning.

後來安裝了Hach BioTector B7000i TOC線上分析儀來代替原先的高溫燃燒氧化TOC分析儀。 Steinbeis製紙廠內的污水處理廠經理說:“ BioTector在一啟動之後就開始運行。” 自那時起,BioTector TOC線上分析儀即持續可靠地提供其監測值,沒有出現任何問題,也無需手動清潔。

At Steinbeis, a 2-channel device is used which monitors both the influent and the e uent wastewater of the treatment plant. The local authority has agreed to approve the reporting of organic residues through TOC values once the correlation between TOC and COD values has been demonstrated.

Steinbeis製紙廠使用BioTector 2通道TOC分析儀,可同時監測處理廠的進水和出水。 在證明了TOC和COD值之間的相關性,地方當局即同意批准透過TOC監測值申報有機殘留物。

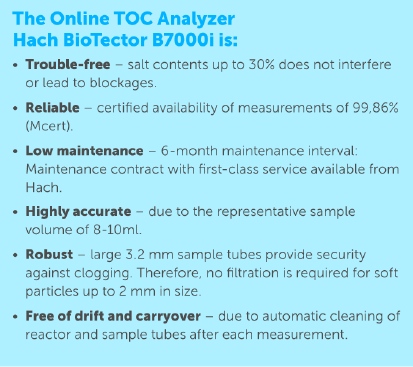

An important advantage of the Hach BioTector B7000i is theautomatic cleaning of the reactor and sample tubes after each measurement. It prevents blockages and carry-over, even with di-cult sample matrices, such as fiber loaded samples. The oxidation of the organic carbon takes place in the BioTector at room temperature in the liquid phase. Salts generally remain dissolved and are flushed out of the device after the reaction so that there are no restrictions due to deposits. As a result, frequent manual cleaning and re-calibration of the device are not necessary.

Hach BioTector B7000i 的重要優點之一是每次測量後自動清洗反應器和水樣瓶。 因此,即使是難處理的水質,例如纖維的水樣,它也能防止堵塞和殘留。 有機碳的氧化作用於室溫下在BioTector分析儀中以液相進行。 鹽通常保持溶解狀態,並在反應作用後從儀器中被沖出來,因此儀器不會因沉積物而受到限制。 因此,操作者不需要頻繁的手動清潔和重新校正設備。

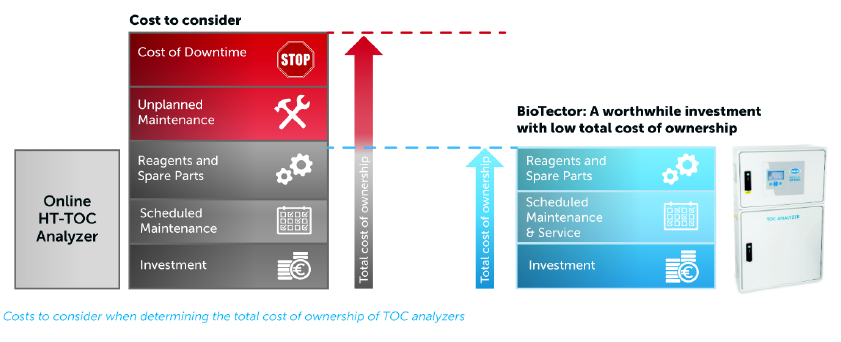

As a result, downtimes are e ectively prevented, and TOC values are permanently and reliably generated with high measuring accuracy. The instrument only needs to be recalibrated every 6 months as part of scheduled maintenance which is taken care of by a service contract with Hach in Steinbeis’ case. During the reagent change, which is necessary every 4 weeks, the instrument doesn’t need to be switched off and can continue to run.

結果,BioTector TOC分析儀有效避免停機時間,並持續可靠地產生高準確度的TOC監測值。 以定期維護來說,B7000i 僅需每6個月重新校正一次。Steinbeis製紙廠的維護合約則是與Hach簽訂並提供服務。 在每4週更換一次試劑的過程中,無需關閉儀器即可繼續運行。

Overall, the Hach BioTector B7000i has a certified measurement availability of 99.86% (Mcert). This corresponds to a plannable downtime of 12h/year in total.

整體來說,Hach BioTector B7000i 的認證測量可用性為99.86% (Mcert)。 這也對應到每年共12h的規劃性的停機時間。

Installation of the TOC Analyzer Hach BioTector B7000i at Steinbeis.

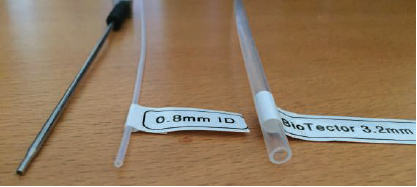

Unlike other TOC technologies, the Hach BioTector B7000i uses large sample tubes with a diameter of 3.2 mm. This provides a good particle passage and a high degree of security against clogging. As a result, sample filtration is not necessary for soft particles up to 2 mm. In addition, a large and therefore representative sample volume of up to 10 ml is used, which ensures a high accuracy of the measurement. Variations due to very small sample volumes can thus be avoided.

與其他TOC分析儀的技術不同,Hach BioTector B7000i 採用直徑為3.2 mm的大型水樣瓶,此設計讓顆粒順暢通過並防止堵塞。 因此,對於2 mm以下的軟顆粒,無需進行水樣過濾。 此外,B7000i採用具代表性的水樣容量,最大為10 ml,這確保測量的高準確度。 因此,可避免由於非常小的水樣量而引起的變化。

在Steinbeis Papier製造廠,Hach線上TOC分析儀安裝於廢水處理廠進水口處,可自動進行淨化過程的控制。與BOD5顯示具有良好相關性的TOC監測值會被傳送到過程控制系統。 過程控制系統則根據容量流量、氨濃度和TOC值來即時管理尿素和磷酸的投放劑量,以確保最佳的營養鹽比率。

Right picture: Hach BioTector sample tube with 3.2mm inner diameter offers safety against blockage. Left picture and center: Tubes with small inner diameter (0.8mm) used in conventional TOC instruments.

Conclusion

To efficiently control a clarification process based on TOC values, the measured values must be reliable and accurate. Only then can the right amount of nutrients be added to the wastewater to ensure that the bacteria perform optimally. In addition to a high availability of measured values and the initial cost of a TOC-Online analyzer, maintenance costs and personnel expenses play a key role. Wastewater from the paper industry is often demanding with high loads of salts and other additives which can lead to malfunctions due to blockages in equipment with high-temperature oxidation, resulting in high maintenance requirements and downtime. The Hach BioTector B7000i TOC analyzer has been specially developed for such difficult wastewater matrices. Despite high dirt and salt loads, it delivers reliably accurate readings with low maintenance requirements.

為有效根據TOC監測值來控制淨化過程,監測值必須持續可靠且準確。 唯有如此,才能對廢水投放適量的營養鹽劑量,以確保細菌發揮最佳作用。 除了監測值的高可用性以及TOC線上分析儀的初始成本之外,日常維護成本和人員費用也扮演關鍵角色。 造紙產業的廢水因為通常有高含量的鹽和其他添加劑而極具挑戰性,而這些內容物可能會導致使用高溫氧化技術的分析儀器造成堵塞,進而可能導致故障,也就容易導致高維護要求和停機時間。 Hach BioTector B7000i TOC 線上分析儀是專門針對此類難處理的廢水水質而設計開發。 儘管污物和鹽分含量很高,B7000i 仍然可以提供持續、可靠並準確的監測值,而且日常維護要求量低。

Authors :

Dr. Isabel Hünig

Patrizia Isabelle Gräf

Katrin Urbanek

| Application Notes (點擊下方標題即可瀏覽原文) | Language | Size | Date | Edition |

|---|---|---|---|---|

|

Steinbeis decides for TOC monitoring withHach BioTector B7000i DOC043.53.30639 |

English US | 710 KB | 2020-09 | Jul20 |