Hach水質系統監測方案於法國垃圾焚化發電廠之應用實績 Water quality at waste-to-energy plants

Background 背景介紹

Veolia operates the Grand-Quevilly waste-to-energy plant to produce thermal and electrical energy. The site has three waste incineration furnaces that generate superheated steam. This then passes through the turbo generator to produce electricity with a nominal power of 32 MW.

The non-recovered energy is condensed and then returned by the feed tank. The efficient operation of these units is critical, as they run approximately 8000 hours per year and require precise control over various parameters to ensure optimal performance and longevity of the equipment.

The primary challenge faced by the customer is the need to continuously monitor and maintain the quality of water and steam used for power generation. This includes ensuring the purity of demineralized water, the quality of feed water to theboilers, and managing the purity of the superheated steam entering the turbines. Any deviation in these parameters can lead to inefficiencies, equipment damage, and potential downtime, which would be costly and disruptive.

Initially, the customer regularly measured water samples in the laboratory, but the decision was then taken to switch to on-line measurement in order to meet the requirements of the insurance companies that cover its installation (in particular the turbine).

Veolia operates the Grand-Quevilly waste-to-energy plant to produce thermal and electrical energy. The site has three waste incineration furnaces that generate superheated steam. This then passes through the turbo generator to produce electricity with a nominal power of 32 MW.

The non-recovered energy is condensed and then returned by the feed tank. The efficient operation of these units is critical, as they run approximately 8000 hours per year and require precise control over various parameters to ensure optimal performance and longevity of the equipment.

The primary challenge faced by the customer is the need to continuously monitor and maintain the quality of water and steam used for power generation. This includes ensuring the purity of demineralized water, the quality of feed water to theboilers, and managing the purity of the superheated steam entering the turbines. Any deviation in these parameters can lead to inefficiencies, equipment damage, and potential downtime, which would be costly and disruptive.

Initially, the customer regularly measured water samples in the laboratory, but the decision was then taken to switch to on-line measurement in order to meet the requirements of the insurance companies that cover its installation (in particular the turbine).

威立雅營運操作一座在法國 Grand-Quevilly城市的垃圾(廢棄物)焚化發電廠,生產熱能和電能。該廠擁有三座廢棄物焚化爐,可產生過熱蒸汽。然後透過渦輪發電機產生輸出功率為 32 兆瓦的電力。

未回收的能源被冷凝後由進料槽收回。保持這些設備的高效率運作很關鍵,因為它們每年運轉約 8000 小時,並且需要對其各種參數進行精確控制,以確保所有設備的最佳效能和使用年限。

此客戶面臨的主要挑戰是需要持續監測和維護用於發電的水質和蒸汽的品質。這包括確保除礦水的純度、鍋爐給水的品質以及管理進入渦輪機的過熱蒸汽的純度。這些參數的任何偏差都可能導致效率低下、設備損壞和潛在的停機,進而造成昂貴的成本和破壞。

最初,此客戶定期在實驗室測量水樣,但後來決定轉為線上監測,以滿足承保其設備安裝(特別是渦輪機)的保險公司之要求。

未回收的能源被冷凝後由進料槽收回。保持這些設備的高效率運作很關鍵,因為它們每年運轉約 8000 小時,並且需要對其各種參數進行精確控制,以確保所有設備的最佳效能和使用年限。

此客戶面臨的主要挑戰是需要持續監測和維護用於發電的水質和蒸汽的品質。這包括確保除礦水的純度、鍋爐給水的品質以及管理進入渦輪機的過熱蒸汽的純度。這些參數的任何偏差都可能導致效率低下、設備損壞和潛在的停機,進而造成昂貴的成本和破壞。

最初,此客戶定期在實驗室測量水樣,但後來決定轉為線上監測,以滿足承保其設備安裝(特別是渦輪機)的保險公司之要求。

Another major challenge was the high pressure and temperature of the sample, which requires cooling and depressurization to avoid damage to downstream water and steam quality monitoring analyzers.

In addition, the limited space available on site for the installation meant that a compact, fully integrated solution was needed that could handle sample conditioning, while adapting to the space available.

The decision for such an analytical solution is driven by the necessity to ensure the longevity and efficiency of the incineration units, minimize maintenance costs, and comply with regulatory standards.

In addition, the limited space available on site for the installation meant that a compact, fully integrated solution was needed that could handle sample conditioning, while adapting to the space available.

The decision for such an analytical solution is driven by the necessity to ensure the longevity and efficiency of the incineration units, minimize maintenance costs, and comply with regulatory standards.

另一個主要挑戰是水樣的高壓和高溫,需要冷卻和減壓以避免損壞下游的水質和蒸汽品質監測分析儀。

此外,現場安裝空間有限,這意味著需要一個體積精巧、可完全整合的方案來處理水樣調節,同時配合可用空間。

選擇此分析方案是為了確保焚燒設備裝置的使用年限和效率、將維護成本最小化並且符合法規標準。

此外,現場安裝空間有限,這意味著需要一個體積精巧、可完全整合的方案來處理水樣調節,同時配合可用空間。

選擇此分析方案是為了確保焚燒設備裝置的使用年限和效率、將維護成本最小化並且符合法規標準。

By implementing continuous analyzers, Veolia aims to enhance the operational reliability of their facilities, optimize energy production, and maintain high standards of environmental performance.

Having 24/7 online measurements in place ensures traceability on water quality, which in the event of a shutdown would be key information to get insurance coverage.

威立雅的目標是透過安裝線上連續監測儀以達到提高其設施運轉可靠度的目標,優化發電,並維持高標準的環境效能。

全天候線上監測可確保水質的可追溯性,倘若發生停止運轉,這將會是獲得保險保障的關鍵資訊。

全天候線上監測可確保水質的可追溯性,倘若發生停止運轉,這將會是獲得保險保障的關鍵資訊。

Solution 解決方案

Water quality should be monitored using either laboratory measurements, online continuous analyzers, or a combination of the two. Laboratory measurements offer a snapshot of the water chemistry at specific moments, but they do not predict changes that may occur in the following hours. To ensure that the water chemistry consistently meets the manufacturer’s standards for boiler and turbine operation, continuous monitoring of the parameters is the most effective approach.

To ensure optimal operation and longevity of plant, a complete measurement system was installed to monitor quality of feed water, demineralized water, and steam going to the turbine.

Monitoring feed water quality helps prevent impurities entering the system, which could cause fouling or damage downstream.

High quality demineralized water is essential to prevent contaminants that might lead to scaling and corrosion in boiler and turbine. Finally, measuring steam going to the turbine is critical, as impurities can erode turbine blades. This can significantly impact efficiency and reduce lifespan of the turbine, resulting in plant shutdown with major technical and financial consequences.

Water quality should be monitored using either laboratory measurements, online continuous analyzers, or a combination of the two. Laboratory measurements offer a snapshot of the water chemistry at specific moments, but they do not predict changes that may occur in the following hours. To ensure that the water chemistry consistently meets the manufacturer’s standards for boiler and turbine operation, continuous monitoring of the parameters is the most effective approach.

To ensure optimal operation and longevity of plant, a complete measurement system was installed to monitor quality of feed water, demineralized water, and steam going to the turbine.

Monitoring feed water quality helps prevent impurities entering the system, which could cause fouling or damage downstream.

High quality demineralized water is essential to prevent contaminants that might lead to scaling and corrosion in boiler and turbine. Finally, measuring steam going to the turbine is critical, as impurities can erode turbine blades. This can significantly impact efficiency and reduce lifespan of the turbine, resulting in plant shutdown with major technical and financial consequences.

使用實驗室測量、線上連續分析儀或是結合兩者來監測水質。實驗室測量協助快速了解某特定時點的水化學狀況,但無法預測接下來幾個小時可能發生的變化。為確保水化學始終符合鍋爐和渦輪機的運作標準,持續監測參數是最有效的做法。

為確保廠區的最佳運作和長使用年限,安裝一套完整的測量系統來監測給水、除礦水和進入渦輪機的蒸汽的品質。

監測給水品質協助防止雜質進入系統,以避免下游設備結垢或損壞。

高品質的除礦水對於防止可能導致鍋爐和渦輪機結垢和腐蝕的污染物至關重要。最後,測量進入渦輪機的蒸汽很關鍵,因為雜質會腐蝕渦輪葉片。這會嚴重影響效率並縮短渦輪機的使用年限,導致廠區停機,造成重大的技術和財務後果。

為確保廠區的最佳運作和長使用年限,安裝一套完整的測量系統來監測給水、除礦水和進入渦輪機的蒸汽的品質。

監測給水品質協助防止雜質進入系統,以避免下游設備結垢或損壞。

高品質的除礦水對於防止可能導致鍋爐和渦輪機結垢和腐蝕的污染物至關重要。最後,測量進入渦輪機的蒸汽很關鍵,因為雜質會腐蝕渦輪葉片。這會嚴重影響效率並縮短渦輪機的使用年限,導致廠區停機,造成重大的技術和財務後果。

Parameters and instruments 監測參數和儀器 :

(1) Degassed Cationic Conductivity Panel (DCCP): Hach 9525

(2) Silica: Hach 5500sc Silica analyzer

(3) Specific Conductivity: Hach 8315 Conductivity Sensor and 9500 controller

(4) pH: Hach 8362 Sensor for ultra pure water and 9500 controller

(5) Dissolved oxygen: Hach 9582 sc DO Sensors

(1) Degassed Cationic Conductivity Panel (DCCP): Hach 9525

(2) Silica: Hach 5500sc Silica analyzer

(3) Specific Conductivity: Hach 8315 Conductivity Sensor and 9500 controller

(4) pH: Hach 8362 Sensor for ultra pure water and 9500 controller

(5) Dissolved oxygen: Hach 9582 sc DO Sensors

Benefits and improvements

Easy installation 安裝容易

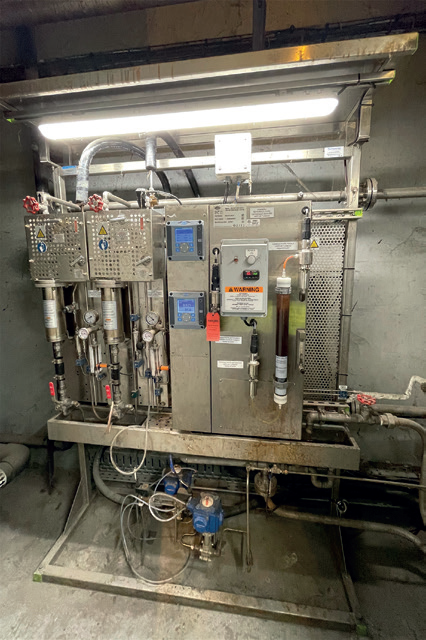

Hach’s standardized, configurable Steam and Water Analysis Systems (SWAS) are prefabricated on rack and include all necessary components to allow analyzers to be easily connected to a hot and pressurized sample. It helps to protect and respect all safety and sample requirements. The modular, robust, and industrial design allows for easy installation, fast startup, and reliable operation.

Easy installation 安裝容易

Hach’s standardized, configurable Steam and Water Analysis Systems (SWAS) are prefabricated on rack and include all necessary components to allow analyzers to be easily connected to a hot and pressurized sample. It helps to protect and respect all safety and sample requirements. The modular, robust, and industrial design allows for easy installation, fast startup, and reliable operation.

Enhanced safety 強化安全性

The SWAS rack solution provides safe operation through shutoff valves for hot samples, safety valves for cooling water, protection screen for hot parts and certified pressure tests. By integrating a hot blow down purging option hot sample line is effectively cleaned to prolong the coolers lifetime and avoid clogging.

Efficient operation 高效率運作

Online instruments allow for real-time measurements of critical parameters like pH, conductivity, and dissolved oxygen. This allows for early detection of incidents like corrosive environment, leakage, etc. and the operator can respond quickly. Hach online analyzers offer improved data quality and consistency by reducing variations in sampling and measurement techniques and by minimizing human errors, which becomes even more critical in low ppb ranges.

Minimized downtime 停機時間最小化

Continuous data collection and diagnosis by Hach’s Prognosys diagnostic system allows for trend analysis and predictive maintenance, minimizing unplanned shutdowns and improving overall plant reliability. Thanks to Hach’s Field Service Plus program regular maintenance, calibration, and certification are performed on instruments by qualified Hach service technicians, ensuring quick resolution of any issues and minimizing downtime.

Cost savings 節省費用

Hach’s turnkey solution helped the plant to save costs in several ways:

The online instruments allow real-time measurements, eliminating the need for manual checks and adjustments. This automation has reduced the labor required for routine monitoring by up to 15 hours a week.

Online monitoring systems provide early detection of corrosion and scaling, preventing unplanned turbine shutdowns and reducing unexpected outages. This has helped the plant to avoid fines for failing to produce electricity in accordance with their contract. According to the site, this could go up to 200 € per hour of not producing electricity.

The 5500sc Silica analyzer offers a sample-in feature that al¬lows for the rapid analysis of a grab sample poured directly into the analyzer, providing immediate results without the need for extensive preparation. This easy-to-use function saves operators time and makes it easier to perform checks and validations.

The SWAS panel integrates an efficient cooler design that ensures the need of less cooling water and a wide sample pressure and temperature range. Additionally, the regenerative cooling option of the degassed cationic conductivity panel eliminates the need for external cooling water, simplifying installation and reducing operating costs.

The SWAS panel integrates an efficient cooler design that ensures the need of less cooling water and a wide sample pressure and temperature range. Additionally, the regenerative cooling option of the degassed cationic conductivity panel eliminates the need for external cooling water, simplifying installation and reducing operating costs.

Hach 的整合系統方案透過多種方式幫助此焚化發電廠節省成本:

線上儀器可以進行即時測量,無需人工手動檢查和調整。自動化方案將每週例行監測所需的勞動力減少多達 15 小時。

線上監測系統可提前發現腐蝕和結垢情況,防止渦輪機意外停機並減少意外停機。這有助於該廠避免因未能按照合約發電而被罰款。據該網站稱,每小時不發電的成本可能高達 200 歐元。

5500sc 二氧化矽分析儀具有進樣功能,可快速分析直接進到分析儀的抓取水樣,無需進行大量準備即可獲得即時結果。此容易使用的功能可節省操作人員的時間並使檢查和驗證變得更加容易。

SWAS 面板採用高效的冷卻器設計,確保僅需更少的冷卻水以及更寬廣的水樣壓力和溫度範圍。此外,脫氣陽離子導電度面板的再生冷卻選項無需外部冷卻水,簡化安裝並降低營運成本。

線上儀器可以進行即時測量,無需人工手動檢查和調整。自動化方案將每週例行監測所需的勞動力減少多達 15 小時。

線上監測系統可提前發現腐蝕和結垢情況,防止渦輪機意外停機並減少意外停機。這有助於該廠避免因未能按照合約發電而被罰款。據該網站稱,每小時不發電的成本可能高達 200 歐元。

5500sc 二氧化矽分析儀具有進樣功能,可快速分析直接進到分析儀的抓取水樣,無需進行大量準備即可獲得即時結果。此容易使用的功能可節省操作人員的時間並使檢查和驗證變得更加容易。

SWAS 面板採用高效的冷卻器設計,確保僅需更少的冷卻水以及更寬廣的水樣壓力和溫度範圍。此外,脫氣陽離子導電度面板的再生冷卻選項無需外部冷卻水,簡化安裝並降低營運成本。

“Having improvements with online measurement specially Silica analyser

have changed my life. With less manual intervention, everything run

smoother and more efficiently.“

Frédéric Leprince

Chemist / Prevention officer at the SNVE plant

have changed my life. With less manual intervention, everything run

smoother and more efficiently.“

Frédéric Leprince

Chemist / Prevention officer at the SNVE plant

Conclusion 結論

High purity water combined with appropriate chemical treatment is essential to control corrosion and scaling in waste-to-energy plants. Veolia needs to monitor the quality of water and steam to ensure safe operation and optimize the chemical treatment scheme.

Hach offers a comprehensive range of laboratory and online instrumentation to address water quality needs. Moreover, Hach is a single source supplier for turnkey complete solutions including sample preparation, panel and rack installations, and professional service.

Veolia’s employees are satisfied with the operation of the online measurement system. It has increased the plant’s safety and efficiency, as well as their confidence in their water quality man-agement.

High purity water combined with appropriate chemical treatment is essential to control corrosion and scaling in waste-to-energy plants. Veolia needs to monitor the quality of water and steam to ensure safe operation and optimize the chemical treatment scheme.

Hach offers a comprehensive range of laboratory and online instrumentation to address water quality needs. Moreover, Hach is a single source supplier for turnkey complete solutions including sample preparation, panel and rack installations, and professional service.

Veolia’s employees are satisfied with the operation of the online measurement system. It has increased the plant’s safety and efficiency, as well as their confidence in their water quality man-agement.

結合高純水與適當的化學處理對於控制垃圾焚化發電廠的腐蝕和結垢很重要。監測水和蒸汽的品質以確保安全運轉並優化化學處理方案。

About the customer 關於該客戶

The SNVE waste-to-energy plant in Grand-Quevilly was established in 1986. It was designed to convert municipal solid waste into energy, significantly reducing the volume of waste sent to landfills and providing a sustainable energy source for the region. SNVE 垃圾焚化發電廠位於法國西北部城市 Grand-Quevilly,建置於 1986 年,其設計是為了將城市固體廢棄物轉化為能源,大幅減少送往垃圾掩埋場的垃圾量,並為該城市地區提供永續能源。

Mission

Veolia manages more than 90 waste-to-energy facilities in the world to treat municipal solid waste while creating renewable energy. Their mission is to resource the world, helping customers address their environmental and sustainability challenges in energy, water and waste. By producing energy from waste, use of fossil fuels is limited, and waste volume and landfill costs and subsequently environmental footprint is reduced. 威立雅於全球管理 90 多個廢棄物能源轉化設施,用於處理城市固體廢棄物並創造再生能源。他們的使命是為世界提供資源,幫助客戶解決能源、水和廢棄物方面的環境和永續性挑戰。透過利用廢棄物生產電力能源,可以限制化石燃料的使用,減少廢棄物量和垃圾掩埋成本,進而減少環境足跡。

Veolia manages more than 90 waste-to-energy facilities in the world to treat municipal solid waste while creating renewable energy. Their mission is to resource the world, helping customers address their environmental and sustainability challenges in energy, water and waste. By producing energy from waste, use of fossil fuels is limited, and waste volume and landfill costs and subsequently environmental footprint is reduced. 威立雅於全球管理 90 多個廢棄物能源轉化設施,用於處理城市固體廢棄物並創造再生能源。他們的使命是為世界提供資源,幫助客戶解決能源、水和廢棄物方面的環境和永續性挑戰。透過利用廢棄物生產電力能源,可以限制化石燃料的使用,減少廢棄物量和垃圾掩埋成本,進而減少環境足跡。

Vision

Veolia’s vision for the SNVE plant includes continuous improve¬ment in process efficiency and energy recovery. The company aims to enhance the plant’s performance, ensuring it meets regulatory standards while providing reliable energy to the local community. 威立雅對 SNVE 工廠的願景包括持續提高製程效率和能源回收。該公司的目標是提高該廢棄物焚化發電廠的效能,確保其符合法規標準,同時為當地城市社區提供可靠的能源。

Veolia’s vision for the SNVE plant includes continuous improve¬ment in process efficiency and energy recovery. The company aims to enhance the plant’s performance, ensuring it meets regulatory standards while providing reliable energy to the local community. 威立雅對 SNVE 工廠的願景包括持續提高製程效率和能源回收。該公司的目標是提高該廢棄物焚化發電廠的效能,確保其符合法規標準,同時為當地城市社區提供可靠的能源。