Hach Solitax sc懸浮固體分析儀於飲用水污泥控制之應用(提高產出並降低費用) Solitax For Drinking Water Sludge Control

Solitax For Drinking Water Sludge Control

Hach Solitax sc懸浮固體線上分析儀於飲用水污泥控制之應用(提高產出並降低費用)

by Ben Brown, Process Control Technician, Northumbrian Water Ltd.

& Dr Hannah Blacknell, Municipal Account Manager, Hach

Hach Solitax sc懸浮固體線上分析儀於飲用水污泥控制之應用(提高產出並降低費用)

by Ben Brown, Process Control Technician, Northumbrian Water Ltd.

& Dr Hannah Blacknell, Municipal Account Manager, Hach

In a recent project with Northumbrian Water Ltd, a Hach Solitax solids measurement probe was used to monitor and control the sludge recirculation flow rate to maintain a solids setpoint via SCADA on two Lamella clarifiers.

Hach英國團隊近期在與英國諾森伯蘭自來水有限公司的一個合作項目中,Hach Solitax 懸浮固體自動分析儀應用於監測和控制污泥再循環流速的程序,透過 SCADA 在兩個薄片淨水器上保持懸浮固體的設定值。

Hach英國團隊近期在與英國諾森伯蘭自來水有限公司的一個合作項目中,Hach Solitax 懸浮固體自動分析儀應用於監測和控制污泥再循環流速的程序,透過 SCADA 在兩個薄片淨水器上保持懸浮固體的設定值。

The site, Wear Valley WTW, suffered from flow restrictions during peak demand periods due to clarifier performance even with large increases in coagulant use.

Recently the site has seen the raw water quality deteriorate due to extreme weather events. Raw water in Burnhope reservoir supplying the site is challenging to treat with a combination of very low conductivity and alkalinity and long periods of very high colour/organic content.

在使用需求高峰期,Wear Valley 水處理廠在大幅增加混凝劑使用量的情況下,淨水器的效能受到流量的限制。

近來,由於極端氣候事件,Wear Valley水處理廠的原水品質有惡化現象。 Wear Valley 水處理廠的供水來自於Burnhope 水庫的原水,由於原水導電度和鹼度極低,且色度/有機物含量非常高,因此處理起來頗具挑戰性。

Recently the site has seen the raw water quality deteriorate due to extreme weather events. Raw water in Burnhope reservoir supplying the site is challenging to treat with a combination of very low conductivity and alkalinity and long periods of very high colour/organic content.

在使用需求高峰期,Wear Valley 水處理廠在大幅增加混凝劑使用量的情況下,淨水器的效能受到流量的限制。

近來,由於極端氣候事件,Wear Valley水處理廠的原水品質有惡化現象。 Wear Valley 水處理廠的供水來自於Burnhope 水庫的原水,由於原水導電度和鹼度極低,且色度/有機物含量非常高,因此處理起來頗具挑戰性。

The change in raw water quality has increased pressure on the coagulant and lime systems, increasing chemical consumption and reducing output. This has required other higher cost sites to maintain customer demand. Wear Valley is a gravity fed works, and higher production here reduces the overall company carbon footprint.

原水品質的變化增加了化學品的使用並降低淨水產出量,因而需要用到其他成本更高的水處理廠來維持客戶的水需求。 Wear Valley WTW 水處理廠為重力系統的水處理廠,其高產出量有助於減少自來水公司的整體碳足跡。

原水品質的變化增加了化學品的使用並降低淨水產出量,因而需要用到其他成本更高的水處理廠來維持客戶的水需求。 Wear Valley WTW 水處理廠為重力系統的水處理廠,其高產出量有助於減少自來水公司的整體碳足跡。

Previous work with Hach at a wastewater treatment site showed that controlling the solids flow rate of a sludge with varying thickness improves process efficiency.

It was hypothesized that this work could be reapplied to a Lamella clarifier drinking water plant to improve the quantity and quality of supplied water.

從Hach公司之前合作過的污水處理廠實例,看到了控制不同厚度污泥的懸浮固體流速可提高處理程序的效率。假設此邏輯可應用於飲用水處理廠(使用薄片淨水器)以改善供水的數量和品質。

It was hypothesized that this work could be reapplied to a Lamella clarifier drinking water plant to improve the quantity and quality of supplied water.

從Hach公司之前合作過的污水處理廠實例,看到了控制不同厚度污泥的懸浮固體流速可提高處理程序的效率。假設此邏輯可應用於飲用水處理廠(使用薄片淨水器)以改善供水的數量和品質。

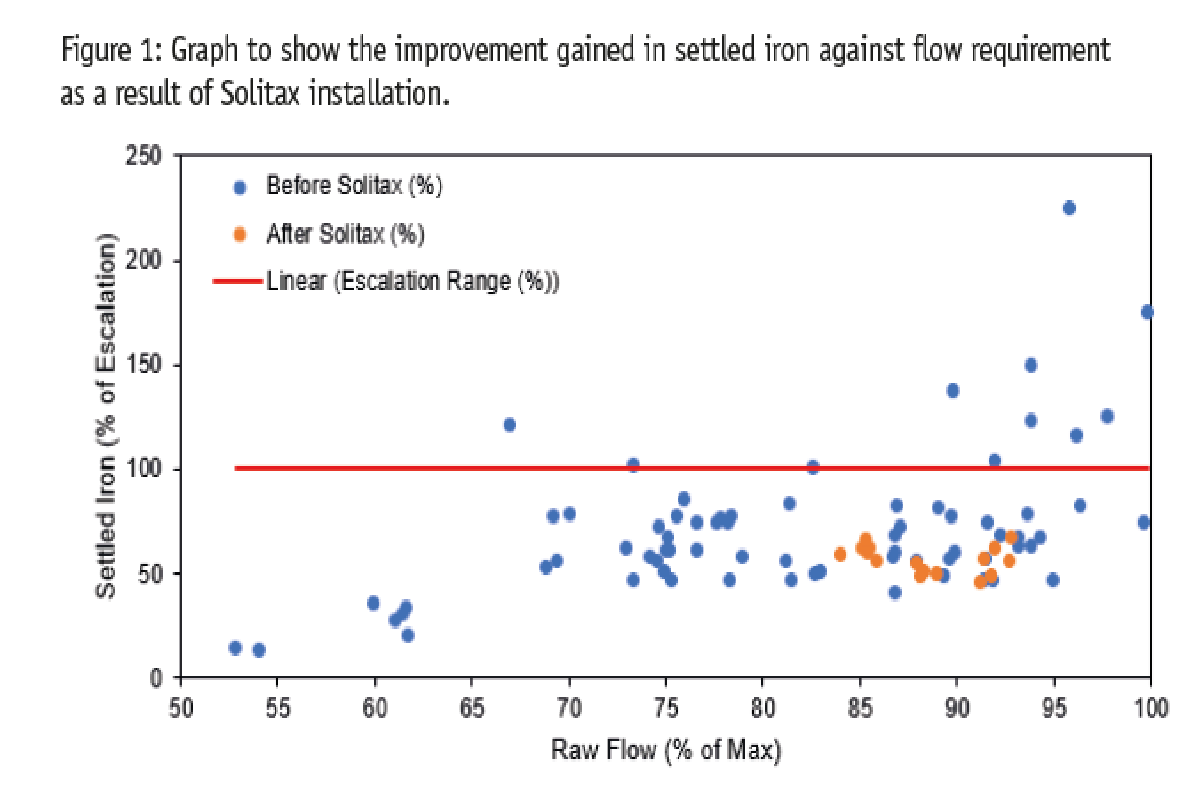

Although there have been large increases in the quantity of water produced by Wear Valley, it was the internal water quality specifications that limited throughput. This graph shows clarified iron concentrations at various flows and the introduction of the Solitax instrumentation has maintained lower settled iron concentrations than seen previously. 儘管Wear Valley水處理廠生產的水量大幅增加,不過內部水質標準限制了產出量。 此圖顯示出不同流量下的淨化的鐵濃度,而 Solitax 懸浮固體分析儀的的導入維持了比以前更低的沉降鐵濃度。

Key Improvements demonstrated include; 主要的改善結果包括:

1. Following the PLC control system installation, ferric dose has been reduced by approximately 15% during high colour raw water conditions.

2. During poor raw water periods, the site is now maintaining almost maximum flows, circa 10-15% higher than previously. Daily production improvements during winter of up to 4ML/d equates to an expected £40,000/year reduction in production costs. During high colour periods a 15% reduction in ferric equates to circa £9,000/year. This added to an expected 5% reduction during the rest of the year would equate to a ferric cost reduction of £15-£20,000 per annum.

3. As well as the improved clarifier performance, sludge draw-off from clarifiers is more constant. Improvements have been seen on press and centrifuge performance as the site does not have a clarifier sludge thickener.

4. The reduction in sludge volume has reduced the probability of emergency tankering and associated costs.

1. 在安裝PLC控制系統後,在高色度的原水條件下,鐵處理藥劑投放量減少了約15%。

2. 在原水狀況不佳的時期,此水處理廠仍幾乎保持最大流量,比以前高出約 10-15%。 冬季每日產量提高 4ML/d,相當於預計每年可減少 40,000 英鎊的生產成本。 在原水為高色度的期間,鐵處理藥劑投放量減少 15%,相當於每年約 9,000 英鎊的費用。 再加上預計在今年剩餘的時間當中減少投放 5% 的藥劑量,相當於每年減少 15,000 至 20,000 英鎊的鐵處理藥劑費用。

3. 除了改善的淨水器效能外,淨水器中的污泥排出狀況更加穩定。 由於此水處理廠沒有淨水器污泥增稠器,因此觀察到壓榨機和離心機的效能也有改善。

4. 由於減少了污泥量,因此降低了需要緊急卡車運輸的可能性和相關成本。

1. Following the PLC control system installation, ferric dose has been reduced by approximately 15% during high colour raw water conditions.

2. During poor raw water periods, the site is now maintaining almost maximum flows, circa 10-15% higher than previously. Daily production improvements during winter of up to 4ML/d equates to an expected £40,000/year reduction in production costs. During high colour periods a 15% reduction in ferric equates to circa £9,000/year. This added to an expected 5% reduction during the rest of the year would equate to a ferric cost reduction of £15-£20,000 per annum.

3. As well as the improved clarifier performance, sludge draw-off from clarifiers is more constant. Improvements have been seen on press and centrifuge performance as the site does not have a clarifier sludge thickener.

4. The reduction in sludge volume has reduced the probability of emergency tankering and associated costs.

1. 在安裝PLC控制系統後,在高色度的原水條件下,鐵處理藥劑投放量減少了約15%。

2. 在原水狀況不佳的時期,此水處理廠仍幾乎保持最大流量,比以前高出約 10-15%。 冬季每日產量提高 4ML/d,相當於預計每年可減少 40,000 英鎊的生產成本。 在原水為高色度的期間,鐵處理藥劑投放量減少 15%,相當於每年約 9,000 英鎊的費用。 再加上預計在今年剩餘的時間當中減少投放 5% 的藥劑量,相當於每年減少 15,000 至 20,000 英鎊的鐵處理藥劑費用。

3. 除了改善的淨水器效能外,淨水器中的污泥排出狀況更加穩定。 由於此水處理廠沒有淨水器污泥增稠器,因此觀察到壓榨機和離心機的效能也有改善。

4. 由於減少了污泥量,因此降低了需要緊急卡車運輸的可能性和相關成本。

Northumbrian Water Ltd will continue to work to optimise sludge recirculation set points. Data analysis during Winter 2021/22 will allow deeper understanding of the process efficiencies needed as the water quality changes with the seasons. Further improvements are expected by altering the solids loading set point depending on real time conditions and flows through the works will be compared to previous years. 諾森伯蘭自來水有限公司將持續努力優化污泥再循環。 針對隨季節而變化的水質,2021/22 冬季期間的數據分析將有助於更深入了解所需要的程序效率。 預計未來將根據即時狀況來調整懸浮固體負荷設定點以期進一步改善,並且也將與往年數據進行比較。

Source :