水中溶氧感測器 Orbisphere M1100 Luminescent dissolved oxygen sensor, 0-40 ppm, with 28 mm Orbisphere fitting

產品編號:M1100-S00H

Monitors oxygen in the beverage production process (bypass)

Sensor for the determination of dissolved oxygen (DO) in beer (bypass) and de-aerated water.

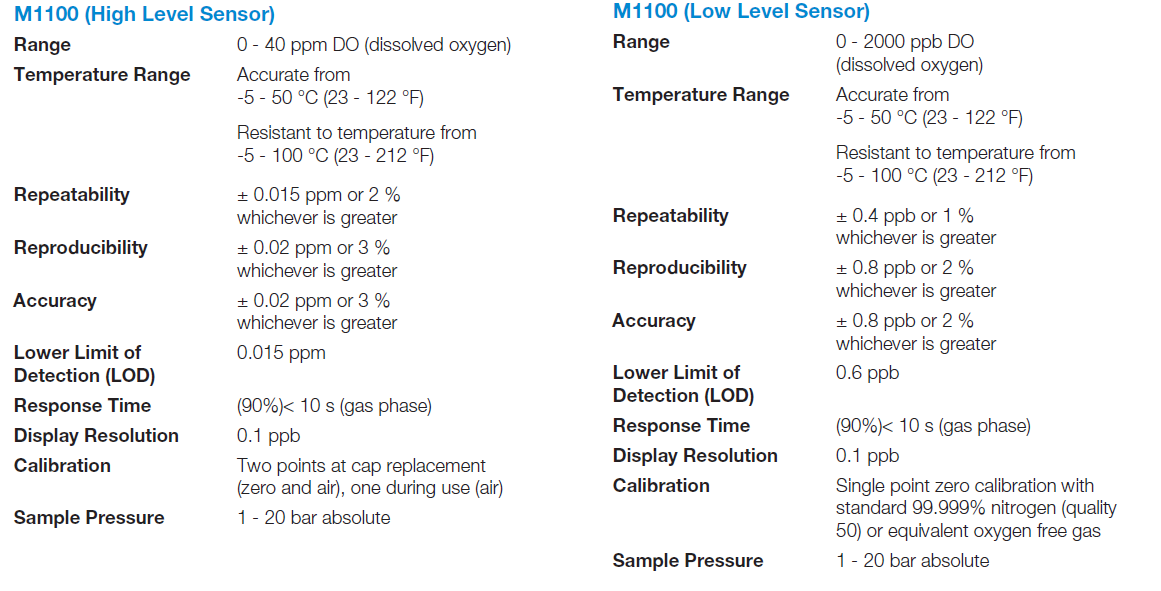

The M1100 Oxygen sensor has an unbeatable precision of 0.8 ppb and a limit of detection of 0.6 ppb. Such accurate measurement readings are essential to control low oxygen levels in beer.

M1100 型光學感測器具有 0.8ppb 高精確度和 0.6ppb 的檢測限。 如此準確的測量值對於控制啤酒中的低含氧量極為關鍵。

The absence of membrane and electrolyte means that the sensor accuracy is unaffected by process changes or pressure shocks. Maintenance and operating costs are also reduced. The sensor has been designed to ensure mechanical robustness and resistance to CIP processes to extend operational lifetime and optimise its total cost of ownership.沒有膜和電解質意味著分析儀的準確性不受製程變化或壓力衝擊的影響。

The quick response time comes from a two second measurement frequency. Capable of measuring accurately at this frequency over a 12 month period.

- Minimal Drift and Annual Calibration 最小漂移和年度校正

- Minimal Maintenance Optical Technology 光學技術設計減少維護量

- Low Level Oxygen Measurement with Accurate ppb 精確 ppb 等級的低濃度氧氣測量

- High Level Oxygen Measurement with Accurate ppm 精確 ppm 等級的高濃度氧氣測量

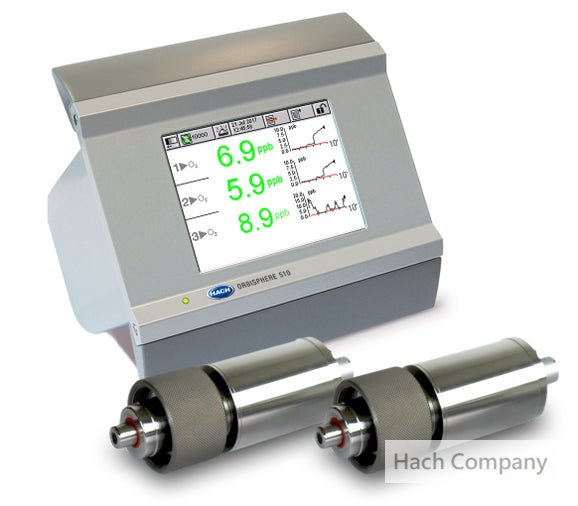

*使用Hach Orbisphere 410/510系列 digital controllers 數位控制主機進行監控

關鍵字 : 純水 溶氧量 線上分析, pure water oxygen analyzer, 純水 溶氧分析儀, 純水 溶氧 監測儀

Sensor for the determination of dissolved oxygen (DO) in beer (bypass) and de-aerated water.

The M1100 Oxygen sensor has an unbeatable precision of 0.8 ppb and a limit of detection of 0.6 ppb. Such accurate measurement readings are essential to control low oxygen levels in beer.

M1100 型光學感測器具有 0.8ppb 高精確度和 0.6ppb 的檢測限。 如此準確的測量值對於控制啤酒中的低含氧量極為關鍵。

The absence of membrane and electrolyte means that the sensor accuracy is unaffected by process changes or pressure shocks. Maintenance and operating costs are also reduced. The sensor has been designed to ensure mechanical robustness and resistance to CIP processes to extend operational lifetime and optimise its total cost of ownership.沒有膜和電解質意味著分析儀的準確性不受製程變化或壓力衝擊的影響。

The quick response time comes from a two second measurement frequency. Capable of measuring accurately at this frequency over a 12 month period.

- Minimal Drift and Annual Calibration 最小漂移和年度校正

- Minimal Maintenance Optical Technology 光學技術設計減少維護量

- Low Level Oxygen Measurement with Accurate ppb 精確 ppb 等級的低濃度氧氣測量

- High Level Oxygen Measurement with Accurate ppm 精確 ppm 等級的高濃度氧氣測量

*使用Hach Orbisphere 410/510系列 digital controllers 數位控制主機進行監控

關鍵字 : 純水 溶氧量 線上分析, pure water oxygen analyzer, 純水 溶氧分析儀, 純水 溶氧 監測儀

Monitors oxygen in the beverage production process 監測飲料製程中的溶氧量

The Orbisphere M1100 optical sensor, together with the Orbisphere 410 one channel and the Orbisphere 510 multi-channel controller, offers a new way of monitoring oxygen in the beverage production process.

Minimal Drift and Annual Calibration 極低漂移,年度校正

The M1100 sensor provides immediate oxygen readings with a measurement frequency of two seconds. The instrument carries consistent readings with no drift for 12 months without calibration (when utilising standard weekly CIP processes), surpassing other optical sensors that display significant drift after only a few months in similar conditions.

Minimal Maintenance Optical Technology 光學技術得以大幅減低日常維護量

The M1100 pioneered the use of luminescent technology in beverage applications, and as a result, the sensor doesn’t require the replacement of membranes or any electrolytes. Additionally, the sensor’s accuracy is unaffected by process changes or pressure shocks—further reducing maintenance. Annual maintenance is limited to just a few minutes for a zero point calibration. Chemicals are not required for this process, making the task easier and safer without reducing measurement precision.

Low Level Oxygen Measurement with Accurate ppb 精確至 ppb等級的低濃度氧測量

The M1100-L sensor has a lower detection level of 0.6 ppb. This highly accurate instrument’s readings are essential to control low oxygen levels in beverage production. As an example, it is critical to control low level oxygen in the post fermentation applications of the brewery to ensure high quality of the final product.

High Level Oxygen Measurement with Accurate ppm 高精準度 ppm 含氧量測量

The M1100-H sensor has a range of 0-40 ppm, and is ideal for use in wort applications, for example. Even in this harsh wort environment, the instrument maintains very good accuracy and minimal drift. Only a yearly maintenance and calibration will be required in most cases.